The hose is essential to every machine, vehicle, and building. It is a type of tube or pipe critical in transporting various liquids, gases, or other materials. In this case, industrial hoses are the most common. These hoses are used in factories for different products, transportation, or storage. However, industrial hoses are of various types. Hydraulic, chemical, dredge hoses, etc., are the most common.

Depending on the different uses, the types of industrial hoses vary. Also, the characteristics of hoses vary based on these various uses. Some industry hoses may have high-temperature resistance, while others may have chemical resistance. As a result, the material used in different industrial hose types varies based on their use. So, while choosing a suitable rubber industrial hose, one must be fully aware of its usage. We have created this article keeping this caveat in mind.

This article will discuss in detail the Industrial Hoses. It will discuss their types, features, and uses. Also, we will discuss how to choose a suitable industrial hose. We will also discuss its maintenance and inspection towards the end of the article. So, take time to read this article. We hope you will get enough idea about Industrial Hoses from here, and it will be convenient to choose the right type.

What Are Industrial Hoses?

As the name implies, these hoses are ideal for industrial applications. According to the definition, industry hoses are flexible tubes or pipes designed to convey many materials. Water, chemicals, gases, oils, food, and beverages are noteworthy in various industrial applications. As a result, the manufacturing materials for industrial hoses are also different. These hoses offer advantages over rigid pipes. These benefits include flexibility, ease of installation, customization, and wear and tear resistance.

- Flexibility: Industrial hoses are highly flexible. It can bend and move to fit into tight spaces and around obstacles. As a result, these hoses are ideal for applications where rigid pipes are impractical.

- Ease of installation: Hoses are very easy to install in any environment. You can connect separate parts quickly and easily. As a result, it reduces downtime and maintenance costs.

- Customization: One of the prevalent advantages of industrial hoses is their customization features. You can make customized sizes based on specific application requirements.

- Resistance to wear and tear: Industry hoses are designed to withstand high pressure and temperature. It can also withstand abrasion and corrosion.

- Versatility: Industrial hoses are suitable for a wide range of applications. Agriculture, automotive, chemical processing, construction, oil, and gas are essential places of application.

Industrial hoses are prevalent in agriculture, chemical processing, construction, etc. These hoses are ideal for withstanding high pressure, extreme temperatures, and harsh environments. Their capabilities depend on the specific application requirements.

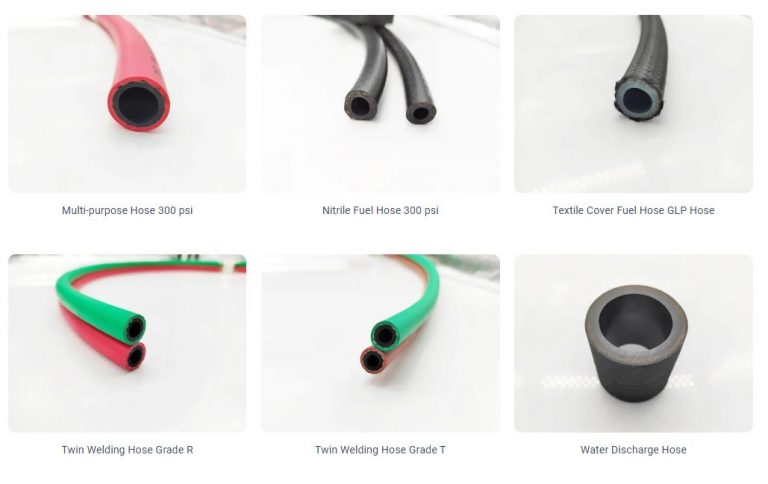

Types of Industrial Hoses

We know that industrial hoses play a crucial role in many applications. Therefore, it keeps a wide range of variants for specific applications. The different industry hoses in the market are ideal for particular application requirements. Chemical hoses for corrosive materials to hydraulic hoses for high-pressure fluids are noteworthy. However, various hoses are available due to the diverse range of liquids and gases. In addition, it is also due to the specific transfer conditions and the unique requirements of different industries. Based on these applications, we have classified industrial hoses into five primary categories.

- Hydraulic hoses

- Chemical hoses

- Food and beverage hoses

- Dredge hoses

- Vacuum hoses

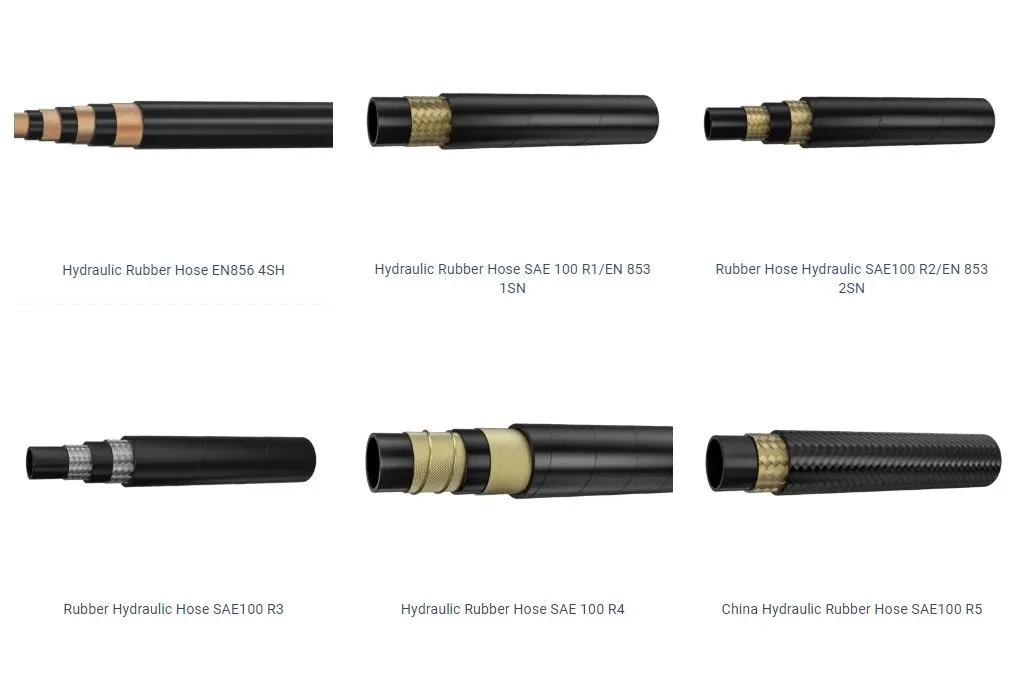

Hydraulic Hoses And Their Types

These industrial hoses are typically the most popular. Hydraulic hoses are also famous as industry hoses. However, industry hoses have some other categories. However, hydraulic hoses naturally have a high-pressure capacity to transfer oil and glycerol. The materials used for these industrial hoses usually are high-strength materials. Synthetic rubber, thermoplastic, or synthetic fibers are noteworthy examples. These materials can withstand high pressures and temperatures associated with hydraulic systems.

There are different types of hydraulic hoses suitable for various applications. Here are three common types of hydraulic hoses you may find in most industrial applications.

- Oil and Gas Hoses: These hydraulic hoses transfer oil and gas fluids in hydraulic systems. They are ideal for withstanding high-pressure conditions. They are made of synthetic rubber or reinforced thermoplastic materials. However, these industrial hoses come in different sizes and lengths to meet specific requirements. “Stainless steel braided hose” and “rubber air hose” are noteworthy examples of this category.

- Air and Water Hoses: These industrial hoses transfer air and water in various hydraulic systems. They are also made of a combination of synthetic rubber or thermoplastic materials. These industrial hoses also come in different sizes to meet specific application requirements. It is important to note that air and water hoses are ideal for low-pressure applications.

- Steam Hoses: These industrial hoses are typically suitable for high-temperature applications. Steam hoses are also eligible for high-pressure applications. As a result, they are ideal for steam cleaning, transfer, and other high-temperature applications.

Chemical Hoses And Their Types

Chemicals are usually highly corrosive. Operating these corrosive chemicals requires high-quality corrosive resistance materials. Chemical hoses are famous for transferring hazardous materials from one place to another. These industrial hoses can withstand harsh environments and extreme temperatures. As a result, it ensures the safe transfer of hazardous materials. However, here are six primary types of chemical hoses:

- UHMWPE Chemical Hoses: UHMWPE stands for high molecular weight polyethylene. This material is highly suitable for transferring a wide range of corrosive chemicals. These industrial hoses are ideal for industries involving aggressive chemicals.

- EPDM Chemical Hoses: EPDM stands for Ethylene Propylene Diene Monomer. This rubber hose material is highly suitable for manufacturing chemical hoses. EPDM hoses are prevalent in pharmaceutical, food processing, and chemical industries.

- XLPE Chemical Hoses: Cross-linked Polyethylene (XLPE) is famous for manufacturing chemical hoses. These industrial hoses can transfer various chemicals, including acids, alkalis, and solvents.

- PTFE Chemical Hoses: PTFE stands for Polytetrafluoroethylene. It is another excellent material for transferring high-temperature and high-pressure fluids.

- Composite Chemical Hoses: These industrial hoses are suitable for transferring aggressive chemicals. Composite chemical hoses are prevalent in the oil and gas industry.

- Chlorine Transfer Chemical Hoses are also famous for manufacturing high-quality chemical hoses. Chlorine transfer hoses are typically made of PVC or PTFE. These industrial hoses are prevalent in the water treatment industry.

Food And Beverage Hoses

When discussing food and beverages, we should first consider food-grade safety. Every food and beverage industry’s equipment and machinery must follow food-grade standards. Food and beverage hoses and fittings with a food-grade safety certificate come in different sizes and lengths. These industrial hoses are widely popular in industries that handle food products.

There are some common types of food and beverage hoses. PVC, silicone, nitrile, and EPDM food-grade hoses are the noteworthy food-beverage hose types. In this case, PVC hoses typically transfer dry and liquid food products. On the other hand, silicone hoses are prevalent in conveying high-temperature food products. However, nitrile and EMDM hoses are ideal for transporting oily, fatty food products.

Dredge Hoses

These industrial hoses are specially designed for mining and dredging applications. Dredge hoses transfer sediment, slurry, and other materials from one location to another. However, these industry hoses are popular in many applications. Offshore dredging, river dredging, and land reclamation are noteworthy examples. Dredge hoses also come in different materials. PVC, rubber, and polyethylene hoses are common types of dredge hoses.

Each of these types of dredge hoses is suitable for conveying different materials. In this case, rubber dredge hoses are ideal for transporting sand and gravel. PVC dredge hoses are suitable for transferring water and liquids. Finally, polyethylene dredge hoses are ideal for conveying acids and other corrosive materials.

Vacuum Hoses

Vacuum hoses transfer air or gas under negative pressure or vacuum. These hoses are widely popular in the manufacturing, pharmaceutical, and construction industries. However, vacuum hoses are typically made of PVC, rubber, or silicone. These materials can withstand negative pressure or vacuum while remaining flexible and durable.

Similar to other industrial hoses, vacuum hoses have some common types. High-temperature, silicone, conductive, heavy-duty, and chemical-resistant vacuum hoses are noteworthy. Overall, vacuum hoses are critical components of many industrial applications. These industrial hoses also come in different sizes and lengths based on specific requirements.

Expert Advice

Selecting a proper hose for your application is essential for ensuring the effectiveness of the operations. Here are some critical points that you should consider while choosing a suitable hose industrial:

- Construction: The construction of industrial hoses includes their material, reinforcement, and cover. Their structure should be ideal for specific applications and environmental conditions.

- Size: The appropriate size and length are crucial to ensure a perfect fit in the system. Industrial hoses that are too small may cause excessive pressure drop. On the other hand, large sizes may be difficult to maneuver and less efficient.

- Effectiveness and performance: While selecting the product, evaluate the hose’s efficacy and performance. Check parameters like pressure rating, temperature range, and flexibility.

- Media compatibility is also essential for selecting the right product. You should check that your hose is compatible with the transferred media. Media compatibility may include chemical composition, temperature, and viscosity. Ensuring the media compatibility will prevent chemical reactions and degradation of the hose.

- Features and Application: Finally, you can check additional features or application-specific requirements. In this case, you can consider abrasion resistance, electrical conductivity, or flame resistance.

Above all, please get in touch with us if you have any questions regarding the industry hose. We have a team of professionals waiting to answer all your questions. In Rentonehose, one of the leading industrial hose manufacturers worldwide, you can find a wide range of industrial hoses. You can also consult with our service team through email, WeChat, WhatsApp, or phone numbers.