Industrial Hose Introduction

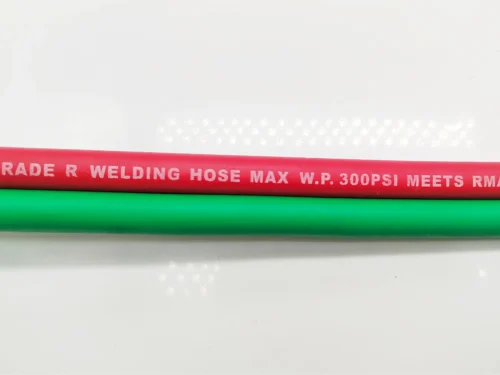

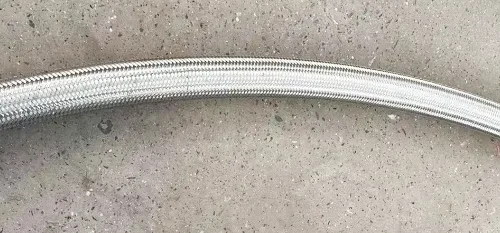

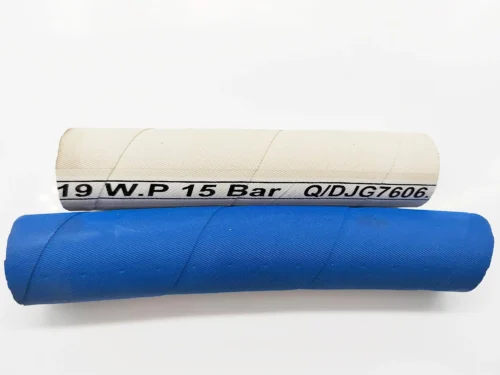

Industrial hoses are mainly used to connect various devices for industrial applications. Industrial rubber hoses are highly flexible and durable. They have good stretchability and bending performance. Therefore, it has also become an irreplaceable substitute for specific industries.

Industrial hoses have entered all walks of life. As a leading industrial hose manufacturer, Rentone has undergone a strict manufacturing process from design and material selection to production. So our products can meet the higher standards for industrial engineering. High-quality industrial hoses can also ensure good adaptability to complex industrial environments.