We all expect to have efficient performance and longevity from industrial hoses. Properly storing industrial hoses can help you to achieve this. We know that industrial hoses are prevalent in a wide range of applications. They contribute to manufacturing, construction, agriculture, and mining applications. They typically transport fluids, gases, and materials under high pressure. However, failing to store hoses correctly can damage them and decrease their lifespan.

Why should you store hoses properly? Keeping the industrial hoses in an organized and controlled manner provides several advantages. First, a designated storage solution ensures their protection from external elements. On the other hand, industrial hoses can be vulnerable to environmental factors like UV light, ozone, and chemicals. In this case, storage solutions shield hoses from these elements.

Moreover, proper storage also reduces the risk of hose kinking or tingling. It is essential when you store hoses for extended periods. Besides, organized hose storage provides easy access and retrieval when necessary. However, this article aims to provide a comprehensive guide on properly storing industrial hoses. It also introduces the popular storage solutions that you can consider for your industrial hoses. Above all, proper storage of industrial hoses maximizes the potential and minimizes the risk of damage.

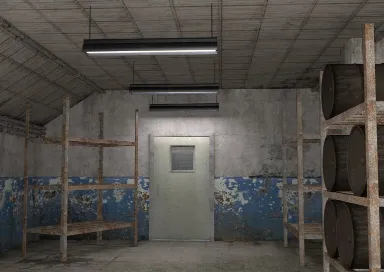

Industrial Hose Storage Solution

A proper storage solution protects the hoses from external elements and environmental factors. Protection from these two elements ensures the industrial hose’s overall performance and reliability. Therefore, choosing the proper industrial hose storage solution is crucial. Here is some popular hose storage that you may consider for your project.

Hose Reels

Reels are cylindrical devices designed to hold and manage industrial hoses. They provide easy winding and unwinding of hoses as needed. There are two primary types of hose reels: manual and motorized. Manual hose reels need manual operation for winding and unwinding the hose. It is a cost-effective solution and ideal for light-duty applications.

On the other hand, motorized hose reels use an electric or hydraulic motor to automate the winding and unwinding of hoses. This feature offers convenience and efficiency in handling industrial hoses. These hose reels are ideal for heavy-duty or high-volume hose usage.

Pros

- Easy to deploy and retract.

- It saves time during the operation.

- Hose reels come with a prolonged lifespan.

- Safety and reduce tripping hazards.

- Space optimation.

Cons

- Sometimes, you may need to help to accommodate the size and length of the hoses you intend to store.

- Hoser reels are open to environmental factors like light, ozone, and chemicals.

Hose Racks

These storage solutions hold and organize industrial hoses in a structured manner. They protect the industrial hoses from tangling, kinking, and damage to the hoses. Hose racks ensure easy accessibility when needed. Like hose reels, hose racks have two types: wall-mounted and freestanding. Wall-mounted are typically mounted on walls or vertical surfaces. It saves floor space and provides a convenient storage solution. However, freestanding hose racks are standalone units. You can place them anywhere you want. They offer flexibility in hose storage and organization.

Pros

- Provide a structured storage system.

- Protect hoses from becoming tangled or twisted.

- It provides efficient space for industrial hoses.

- It also protects the hose from external damage.

Cons

- Limited capacity.

- It needs proper installation, which might need drilling into walls or other surfaces.

- Hose racks occupy physical spaces. As a result, it is not suitable for areas with limited space availability.

- There may be a risk of misalignment or entanglement.

Wall-mounted Storage Systems

These hose storage systems are designed to secure industrial hoses on vertical surfaces, such as walls or partitions. Wall-mounted storage systems provide an efficient and space-saving solution for hose storage. It ensures easy access and organization. There are four types: hose hooks, hangers, track systems, and spring balancers. Hose hoos or brackets hang the hoses on walls. Hose hangers feature multiple hooks or loops to accommodate several hoses simultaneously.

On the other hand, hose track systems consist of a rail or channel mounted on the wall. It allows hoses to slide along the track for easy access and storage. Finally, spring hose balancers use a retractable mechanism to suspend hoses from a wall-mounted unit. It provides effortless hose handling and minimizes fatigue.

Pros

- Free up valuable area.

- Provides easy accessibility.

- It prevents tangling and kinking.

- Flexibility.

- Cost-effective.

Cons

- It may have a limited capacity to store many industrial hoses or longer lengths.

- Proper installation and mounting are required.

- Not suitable for environments with limited wall space.

Hose Cabinets

These hose storage solutions are specially designed for the storage of industrial hoses. Like other types of storage, they also shield hoses from external elements. There are four types of hose cabinets: Wall-mounted, floor-mounted, lockable, and ventilated.

Wall-mounted cabinets are typically mounted on walls. Floor-mounted cabinets stand on the floor and often feature a larger storage capacity. On the other hand, lockable cabinets come with locking mechanisms. Lastly, ventilated cabinets include built-in ventilation or airflow systems to prevent moisture.

Pros

- Protects from environmental elements.

- Allows for easy identification and retrieval of hoses when needed.

- Space efficiency.

- Durable.

Cons

- Higher cost than others.

- Require sufficient floor or wall space for installation.

- Proper installation and mounting are required.

Hose Wooden Box

These hose storage solutions are a type of storage container made from wood. Like other hose storage solutions, it is also ideal for storing and protecting industrial hoses. They offer a portable and customizable solution for hose storage. In addition, it ensures ease of transportation and flexibility in size and design.

There are three wooden hose boxes: Standard, customized, and lined wooden boxes. First, standard hose boxes are essentially rectangular boxes made of wood. They provide a simple storage solution for hoses. Second, customized boxes accommodate the dimensions and requirements of the hoses being stored. Third, Lined hose containers feature internal lining or padding to provide additional protection.

Pros

- Portable and easy to access

- Protect from impact, abrasion, or exposure

- Offer customized solution

Cons

- Maybe susceptible to moisture damage or warping

- Wooden boxes attract pests such as termites or rodents. It poses a risk to the stored hoses.

- Limited durability

Hose Trolleys

Pros

- Mobility

- Quick and convenient access to hoses

- Feature built-in hooks or racks

- Eliminates the need for manually carrying heavy hoses

Cons

- Trolleys need enough space for maneuvering and storage.

- May be limited to the number or length of hoses that can be stored

- Require frequent maintenance and occasional repairs

How to Store Industrial Hoses

Appropriately storing industrial hoses is essential to ensure their efficiency. It provides the durability and reliability of hoses. In addition, it prevents damage, leaks, and premature wear. Proper storage also minimizes business downtime and improves operational efficiency. Moreover, it enhances workplace safety and saves time and costs in the long run.

Storage Environment, Temperature, And Humidity

First, we should ensure the proper temperature control for hose storage. An optimal temperature range can be between 10°C to 24°C. It helps prevent the degradation of hose materials. On the other hand, extreme temperatures create brittleness, cracking, or loss of flexibility in hoses. Moreover, controlling humidity is also necessary to prevent moisture damage. It is important to note that excessive moisture can promote mold, mildew, or corrosion.

Second, ensure protection against various environmental factors. In this case, ozone, sunlight, and certain chemicals can deteriorate hoses over time. Therefore, it is crucial to install the barrier against these environmental factors.

Preparing Industrial Hoses For Storage

The next step that you should do is to prepare your industrial hoses. While preparing industrial hoses for storage, we have divided this step into four primary stages.

A. Cleanliness And Inspection

Cleanliness and inspection are the most crucial steps before storing the industrial hoses. Here are three cleanliness and inspection steps that you should do:

- Cleaning Hoses Before Storage: It is necessary to remove dirt and debris accumulated during use before storing the hoses. Follow the manufacturer’s guidelines for this step.

- Visual Inspection: You can inspect hoses to identify damage, wear, or degradation signs. In this case, look for cracks, abrasions, bulges, or leaks that affect the hose’s performance.

- Addressing Issues And Repair If Necessary: If you address any problems, fix them immediately. The type of repair depends on the severity of the case. Some standard repair methods include patching, replacing fittings, or replacing the entire hose.

B. Proper Drying

Next, after cleanliness and inspection, it’s time for your hoses to dry appropriately. Moisture trapped inside the hose creates mold, mildew, corrosion, or degradation. Therefore, before storage, it is essential to ensure that the hoses are completely dry. Some standard drying techniques include air-drying racks or stands and moisture-absorbing materials. You can also hang them in a well-ventilated area.

C. Removal of Pressure Tension

Before storing industrial hoses, release the internal or external pressure. You prevent potential accidents, hose bursts, or damage during storage or handling. You should follow the appropriate procedures to depressurize the hoses. Consulting with the manufacturer is recommended in this case.

In addition, when cooling or arranging hoses for storage, it is necessary to ensure no excessive tension, bending, or twisting. It is important to note that improperly stored hoses can develop permanent kinks, deformations, or weak spots.

D. Proper Coiling Technique

The final preparation that you should take for your industrial hoses is following the proper coiling technique. Proper coiling technique prevents kinks, tangles, and damage. Besides, coiling hoses correctly ensures that they maintain their shape and flexibility. As a result, it makes them easier to handle and reduces the risk of potential failures. Here are three standard coiling methods:

- The single coil method involves coiling the hose in a single loop. First, start by holding one end of the hose and twist it in a circular motion.

- The figure-eight coil method is appropriate for longer industrial hoses as it prevents kinks. To begin, create a loop at one end of the hose and then cross it over itself to form a figure-eight pattern.

- The reel coiling method is the most popular coiling method for industrial hoses. It offers efficient storage for hydraulic hoses. The technique is simple. Place the hose on the reel and ensure it is properly aligned and centered. Now rotate the reel handle or activate the motor to wind the hose evenly and tightly onto the reel.

Labelling And Organizing

Labeling and organizing are necessary for efficient management and safe operations. Clear labeling provides a quick and accurate identification solution. It minimizes the risk of using the wrong hose for specific applications. Proper labeling typically offers crucial information about industrial hoses. It may include pressure ratings and inspection dates.

Organized storage systems ease access to hoses when required, saving time and cost. Rapid retrieval of hoses reduces operational downtime, improves efficiency, and minimizes disruptions. Efficient inventory management optimizes hose use and minimizes waste, resulting in cost-effective operations.

Regular Inspection During Storage

Regularly inspecting hoses during storage is crucial for maintaining their integrity and performance. Conduct inspections at appropriate intervals to identify any signs of damage or degradation. Take prompt action to address any issues found to prevent further damage. Moreover, periodically rotate stored hoses to preserve their condition and minimize unnecessary wear.

Conclusion

Proper hose storage is essential for maintaining the performance of industrial hoses. Following the instructions above, you can easily protect your hoses from all hazards. However, efficient labeling provides quick identification, inventory management, and compliance with safety regulations. Finally, conducting inspections at appropriate intervals identifies the signs of damage or degradation.

These practices reduce downtime, enhance safety, and improve cost-effectiveness for industrial operations. Efficient inventory management optimizes utilization and minimizes waste. Easy access to hoses saves time and prevents disruptions. Regular inspections and prompt issue resolution ensure reliable hose operation.

Rentonehose is a trusted choice for your project when considering industrial hose suppliers. Their high-quality hoses are designed to withstand demanding industrial environments. Besides, they are backed by reliable customer service. Consult their experienced team to find the best hose solutions tailored to your needs.