Leading Hydraulic Hose Manufacturer

Rentone Hose is a leading hydraulic hose manufacturer in China. The company has been in the hydraulic hoses industry for over 10 years. The company has advanced equipment and technology. We have gone extrusion and compounding plants. Our product line meets industry standards, ensuring high-quality hydraulic hose manufacturing. As a reliable hydraulic hose supplier, we can offer a variety of hydraulic rubber hoses. We can meet the different requirements of our global customers.

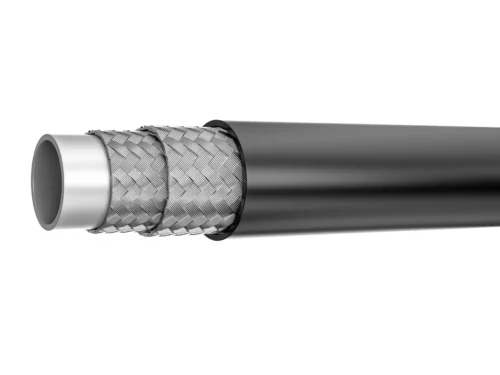

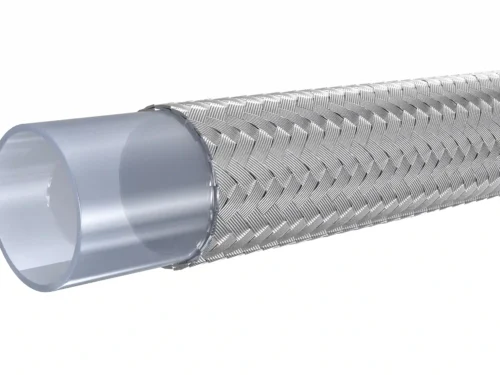

Rentone Hose has a diverse product portfolio of hydraulic rubber hoses for various applications. The hydraulic hoses include high-pressure wire braided hoses, high-pressure and ultra high-pressure wire spiral hoses, fiber braided hoses, and textile braided hoses. We can also offer custom hydraulic hose services according to customer requirements.