Hydraulic systems are integral to many machinery, production lines, and automotive vehicles. Hydraulic hoses are an essential component of these hydraulic systems. Some typical applications of hose and hydraulics include construction, agriculture, and manufacturing. A hydraulic rubber hose also transmits fluids, such as oil, and powers machinery or equipment.

A good quality hydraulic system always ensures effective and reliable operations. On the other hand, a wrong hose can lead to potential safety hazards, such as hydraulic hose failure. Therefore, choosing a suitable hydraulic hose for your applications is crucial. Keeping that importance in mind, we have prepared this article for our readers.

This article will negotiate the selected hydraulic hose with various factors. We will begin with understanding your system requirements. Then, we will jump into the basic parameters of hydraulic hoses and fittings. Later, we will discuss other factors, such as applications, environmental factors, and safety. Understanding these factors lets you select the ideal hydraulic hose for your project.

How to Select The Right Hydraulic Hose For Your Application

Due to the ease of technology, many industries can easily make quality products. Choosing the right product from these many brands is overwhelming. Therefore, following the factors below is necessary to choose the right one from these numerous options. Basic parameters such as size and pressure rating are most critical to understand.

Different applications and environmental factors also differentiate the qualities of hydraulic pipes. Moreover, we should also consider the safety performance of the product. This section will discuss the factors to consider when selecting the proper hydraulic hose for your application. By following these guidelines, you can ensure optimal system performance, efficiency, and safety.

Understand Your System Requirements

Before selecting a suitable hose, the first thing is to understand your system requirements. This step involves knowing the value of pressure, temperature, flow rate, and the type of transferred fluids. This step is necessary. Because it can ensure that the hydraulic hose you choose can handle your system’s demands, selecting the incorrect hose can lead to system inefficiencies, damage, and even safety hazards. For example, a high-pressure system needs a hose with a pressure rating that exceeds the maximum operating pressure.

On the other hand, you should also know what type of fluid you will transfer through the hose. In this case, different fluids provide varying physical and chemical properties with the chosen hose. So, choosing a hose compatible with the fluid used in your system is essential. Moreover, you should also know the operating temperature level of your system. In this case, an appropriate hydraulic rubber hose is necessary to avoid failure.

After you know your system requirement, you can compare the following factors from numerous options. This step should be considered at the beginning of all the steps below. Then, we can evaluate the following factors very quickly. Therefore, it is essential to know the system requirements before choosing a suitable hydraulic hose.

Learn The Basic Parameters of Hydraulic Hoses

Hydraulic hoses come in various sizes and lengths. It may include varying pressure ratings and manufacturing materials to suit different applications. So, choosing the right product can be challenging if you need help understanding the basic parameters. The following seven are the most critical parameters that you should consider first.

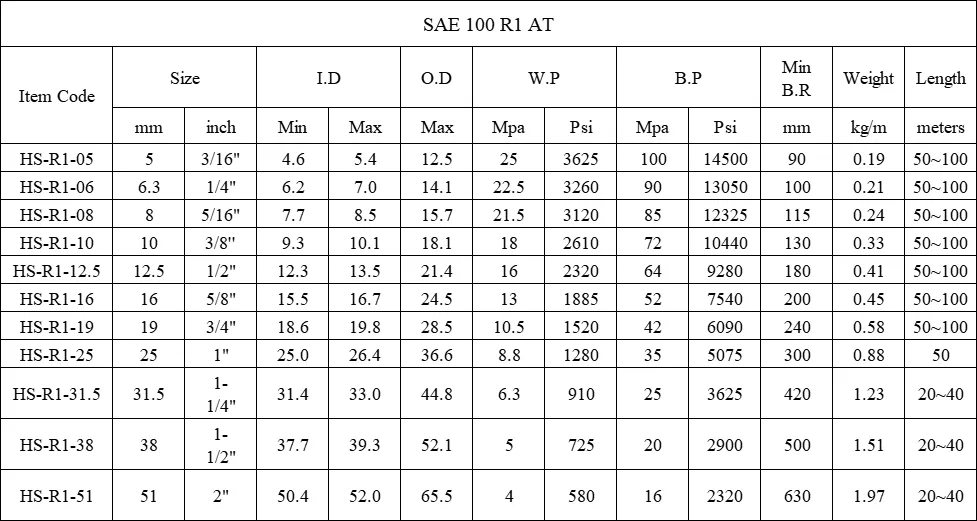

TDS of Hydraulic Rubber Hose SAE 100 R1 AT

A. Size

The size of a hydraulic hose is the most critical parameter to consider during the selection process. You may find these values on the technical data sheet of the selected products. Typically, you can find it on the manufacturer’s website. While considering the size, you should check the following parameters carefully:

- The inner diameter (ID) of the hydraulic hose determines the size of the opening where fluid flows through.

- The outer diameter (OD) is the measurement of the total diameter of the hose. It also determines the size of the end fittings.

- The hose length is the standard length of the hydraulic pipe. You should find the most appropriate length because it affects the hydraulic system’s performance.

- The minimum bend radius (BR) is the tightest radius at which a hydraulic hose can be bent without affecting the system’s performance.

For example, the above picture highlights the available size of Hydraulic Rubber Hose SAE 100 R1. This table demonstrates 11 product models offering 11 different sizes of industrial hose pipe. The inner and diameter range from 4.6mm to 52mm and 12.5mm to 65.5mm, respectively. However, the bend radius ranges from 90mm to 630mm, followed by lengths from 20 to 100 meters.

B. Pressure Rating

A high-pressure hydraulic hose is designed to withstand pressure to transmit hydraulic fluids. The pressure rating of the selected hydraulic pipe determines the maximum pressure that a hose can safely handle. In this case, you should consider two primary parameters: working and burst pressure. The maximum working pressure (WR) refers to the normal operating pressure of the hose. On the other hand, burst pressure determines the maximum pressure the hose can withstand before it fails.

For example, the above table highlights the technical data of Hydraulic Rubber Hose SAE 100 R1. It says that the available model of this product can withstand working pressure from 4Mpa to 25 Mpa. On the other hand, the burst pressure ranges from 16 Mpa to 100 Mpa.

C. Transferred Fluids

Hydraulic hoses must be compatible with the fluid that they will carry. Incompatible hydraulic fluids may lead to hose failure, damage to the hydraulic system, and even personal injury. However, different types of hydraulic fluids provide varying properties affecting the hose’s performance. For example, water-based fluids are less flammable but cause corrosion and rust. On the other hand, petroleum-based fluids are more flammable but less likely to cause corrosion and rust. While considering suitable liquids, also know their chemical compatibility, viscosity, and abrasiveness.

D. Temperature Conditions

Hydraulic hoses can be subjected to a wide range of temperature conditions. These conditions apply to fluid and the environment in which the hose will be used. In this case, you should select a hydraulic hose that can withstand the applicable temperature conditions. For example, the operating temperature of Hydraulic Rubber Hose SAE 100 R1/EN 853 1SN is -40℃ – +100℃ (-40℉ – +212℉). Here are the three key factors to consider when it comes to temperature:

- Temperature range of the fluid: Different hydraulic fluids provide varying temperature ranges. Therefore, it is crucial to choose a hydraulic rubber hose that can handle the temperature range of the transferred fluid.

- Temperature range of the environment: The operation environment also affects the hose’s performance. For example, if your hydraulic system works in extreme heat or cold operation, choose a hose that can withstand those conditions.

- Compatibility of the hose material: The material of the hose also affects its ability to withstand temperature. Some materials may become brittle in cold temperatures and may break at high temperatures.

E. Hose Material

A hydraulic hose can be made from a variety of materials. Each of these materials provides its own set of advantages and disadvantages. However, the most popular materials used in hose manufacturing are rubber, thermoplastic, and metal.

Rubber hoses are famous for their durability, flexibility, and affordability. They can handle various temperature ranges. However, they also provide excellent abrasion, ozone, and UV resistance ability. They are not suitable for high-temperature applications.

Thermoplastic hoses are lightweight, flexible, and resistant to chemicals and abrasion. They can handle high-temperature applications. As a result, thermoplastic rubber hoses are prevalent in heavy-duty machinery. These hydraulic hoses are not suitable for low-temperature applications.

Metal hoses are the most durable and long-lasting type of hydraulic hoses. They can handle extreme temperatures and high pressure. However, one of the downsides of these hydraulic hoses is their cost. Metal hydraulic hoses are more expensive than the other two materials.

F. Hose Reinforcement

It is also one of the essential factors that you should consider during the hydraulic hose selection process. The reinforcement layer provides strength and durability for high pressure and frequent use. However, there are two types of hose reinforcement: braided and spiral.

Braided hoses have one or two layers of wire or textile braid. These types of hoses are excellent for flexible operation. They also provide resistance to kinking. On the other hand, spiral hoses have multiple layers of wire spiral. These types of hydraulic hoses offer greater strength and durability. Although, these hoses are not suitable for flexible operations.

G. End Hydraulic Fittings

The final parameter you should consider is the type of end hydraulic fittings you use for your hydraulic hoses. Selecting your hose’s hydraulic fittings ensures a safe and leak-free connection. However, different types of end fittings are also available in the market. Crimp and reusable hydraulic hose fittings are some noteworthy types.

Crimp hydraulic fittings are permanently attached to the hose. These hydraulic fittings are more secure and provide reliable connections. On the other hand, reusable end fittings are adjustable. You can connect and detach multiple times. As a result, these types of end fittings are more flexible. However, they are less secure than crimp fittings.

Importance of Considering Specific Application

The specific use of hydraulic hose also determines the type of hose you need for your project. For example, the hydraulic hose used in the mining industry will differ from those used in agriculture. A hydraulic hose pipe used in a high-temperature environment should have a higher temperature rating. So, understanding the specific application is crucial in selecting a suitable hydraulic hose. In this case, during the selection process, you should know the following answers to find the ideal choice.

- What type of equipment does the system use?

- In which industry will the equipment be used?

- What is the location of the equipment?

- How much is the frequency of use?

- What type of fluid will be transferred through the equipment?

- What are the specific operating conditions?? Is it indoor, outdoor, or extreme temperatures?

Consider Environmental Factors

Different environmental factors also affect the performance of a hydraulic hose. Therefore, when selecting a suitable hose, it is necessary to consider the following factors.

- Temperature range: You should know the maximum and minimum temperatures to which the hydraulic hose will be exposed. It includes the temperature of the fluid being transferred and the surrounding environment.

- Chemical compatibility is also necessary to test the hose material with the transferred fluid through the hose.

- UV exposure: If your application involves sunlight or UV exposure, you better choose a UV-resistant cover. By considering this, you can prevent the degradation of your hydraulic hose.

- Humidity and moisture: Extreme humidity and moisture can also affect the durability of the hydraulic hose.

- Abrasion resistance: Hydraulic hoses can face abrasion from various sources. Contact with other surfaces or debris can degrade the hose’s lifespan.

- Electrical Conductivity: Hydraulic systems are sometimes prone to electrostatic charges. It happens by friction between the oil flowing and the system’s surface. This static charge’s strength depends on the oil’s conductivity and flow rate. Therefore, select a hose with electrical conductivity to prevent the build of static charge.

Safety Considerations

Hose whip or hose bursts are common safety threats to a hydraulic system. Although, it shouldn’t be said that a hose burst failure is always a common incident. A hose failure typically creates production downtime or environmental contamination concerns. Therefore, safety is necessary before choosing the hydraulic hose for the applications.

It would help to use something other than economics as the only primary hose selection criteria. By doing this, you can quickly leave human risks very high. The above factors discussed, and the budget should be considered before choosing the final hydraulic hose. Above all, proper selection, installation, and maintenance can prevent hose failure. In addition, it will also protect against injury and damage.

Conclusion

The selection process of hydraulic hoses is necessary for ensuring your system’s optimal performance and safety. It would be best if you followed the above steps one after another. Following the sequence will help you with reducing research time. In addition, it will also help you find the best possible choices for your project.

Contact us if you have questions about hydraulic hoses and their specifications. Rentone hose is one of the most popular products from seashore rubber. Seashore Rubber keeps a team of experts in the customer service section. You can consult them for more information if you need more than this article.