Only a few manufacturing companies in the past needed to transport chemicals from one place to another. Over time, engineers learned how to transport chemicals safely and efficiently. PVC hoses for this job are excellent solutions for most industries nowadays. It is not only cheap but also has a higher pressure rating.

Since chemical processing and fluid transfer can be hazardous, we should take proper precautions. Choosing a suitable PVC hose is the most crucial step that you should follow. An ideal choice ensures safe and efficient operation. Consider several factors when selecting the proper PVC hose. Material composition, temperature range, pressure rating, and hose size are notable. Failing to take these factors into account can result in severe consequences.

Let’s say you’ve got a PVC hose with a lower pressure rating than you need for your project. This PVC hose will cause hose failure and leaks in your project. Again, incompatible PVC hoses can cause contamination, which eventually becomes unusable.

This article provides a comprehensive guide on some factors you should consider when selecting. In addition, we will also explore the steps of finding a suitable PVC hose manufacturer. Above all, this article will be an excellent guide for choosing the best PVC hose for your project.

What is A PVC Hose?

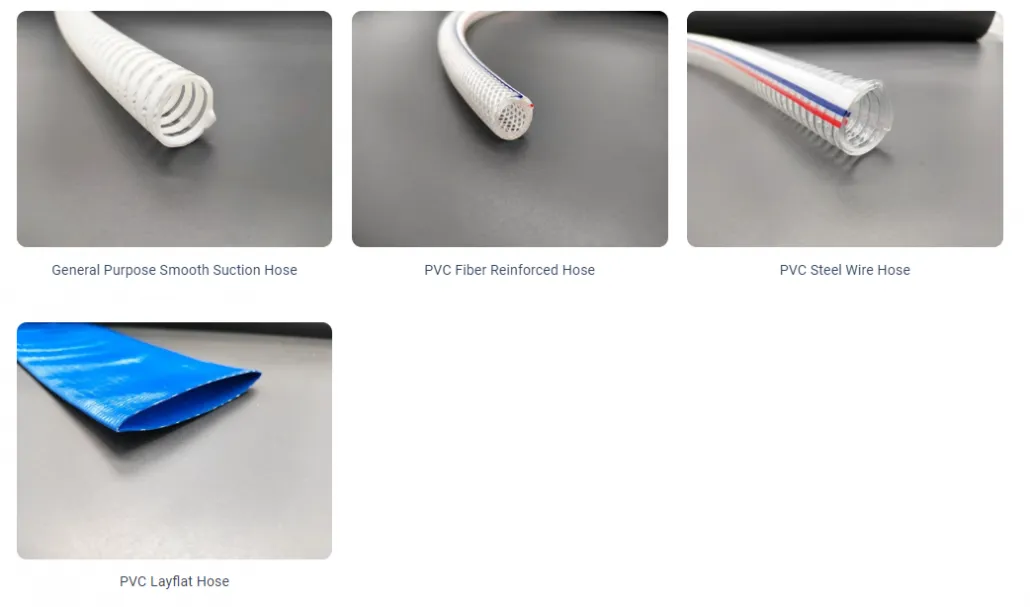

PVC stands for polyvinyl chloride. As the name implies, the main ingredient for PVC hose is polyvinyl chloride. It is a flexible tubing used to transfer liquids or gases. PVC hose comes in many sizes, colors, and grades, designed to meet specific industry requirements. You may find a variety of structural properties in PVC hoses. Some notable types are PVC fiber-reinforced, PVC steel wire hose, PVC suction hose, and PVC layflat hose. Each class offers a specific level of flexibility, chemical and UV resistance, or flame retardancy.

One of the primary advantages of using PVC hose is its affordability. PVC hose is typically less expensive than rubber or silicone hoses. Besides, PVC hoses are lightweight, flexible, and easy to handle. As a result, they are ideal for use in frequent movement or repositioning applications. Although PVC hoses provide many benefits, they have some disadvantages too. They are not suitable for use in high-temperature applications. In high-temperature applications, PVC can melt or deform. Additionally, some PVC hoses may not be compatible with some chemicals.

PVC hose is a versatile, cost-effective solution for various liquid and gas transfer applications. It is essential to consider the hose’s material composition and structural properties carefully. As a result, you can ensure that your chosen hose is compatible with your project system.

How to Choose A Suitable PVC Flexible Hose?

When it comes to selecting a suitable PVC flexible hose, there are several important considerations to take into account. You must choose the ideal products to avoid safety hazards, equipment damage, and increased operating costs. This section will explore the key factors to consider when selecting a PVC hose.

Application

Before installing or replacing a PVC hose, it is crucial to determine its intended use or application. We should know additional questions to ensure the hose meets the application’s requirements. These may include inquiries into the intended use or application of the hose and any specific requirements needed.

- Where will you use the hose?

- What type of fluid or gas will you transfer through the hose?

- What is the ambient temperature?

- Thread end connection type

- What is the working and surge pressure?

- What are the environmental factors?

- Is there any abrasion?

Hose Size

The size of the PVC flex hose is the next factor you should consider. The inner diameter of the hose should be sufficient to keep pressure loss to a minimum. A correct inner diameter is also necessary to prevent damage caused by heat generation or excessive turbulence. Find the proper size from the sizing nomographic chart based on your system requirement. For replacement, read the lay line printed on the original products. If the lay line is painted over or worn off, you should cut the piece and measure the inside diameter for size.

It is important to note that before you cut the original hose, you should measure its assembly length. Hose length is also a crucial factor you should consider.

Temperature Range

The temperature range of a PVC hose determines the minimum and maximum working temperature. When choosing the hose, it is crucial to consider two temperature areas. These are fluid temperature and ambient temperature. In addition, it is also essential to exercise caution when routing the hose near hot manifolds. In extreme cases, a heat shield is recommended.

Follow the manufacturer’s guidelines to determine the appropriate fluid temperature and limits. It is essential to consult these guidelines to ensure the selected hose can withstand certain temperatures.

Pressure Rating

The pressure rating of a PVC flex hose refers to the maximum amount of pressure that the hose can withstand without rupturing or failing. Choosing a hose with an appropriate pressure rating is essential to ensure safety and equipment protection. For instance, if your project deals with high-pressurized gas or liquid, it must withstand that pressure.

Using hoses on applications with pressure spikes exceeding the working pressures of the hose is not recommended. It is essential to note this to ensure the longevity and safety of the PVC hose in your application.

Chemical Resistance

You must check its compatibility if you require a PVC flex hose to transfer certain chemicals. PVC hoses are specially designed to handle a wide range of fluids. But still, they are not universally resistant to all types of chemicals. An inappropriate PVC hose can create contamination of the substances. Moreover, it also increases the operating costs due to frequent replacement. Therefore, selecting a PVC hose that is chemically compatible with the specific fluids is essential.

In chemical processing applications, the selected PVC hose must withstand the chemical. The chosen hose must prevent degradation, leaks, and safety hazards.

Abrasion Resistance

Hoses often face rubbing, scraping, or mechanical wear during use. It can damage or wear to the outer layer of the hose. As a result, your hose becomes weak and ultimately leads to failure. Therefore, choosing a PVC hose with excellent abrasion resistance capability is essential.

Abrasion may be caused by many factors, such as rough surfaces, repeated bending, or sharp edge exposure. In this case, an ideal flexible PVC pipe can help extend its lifespan and reduce maintenance costs.

Flexibility

Flexibility is also an essential factor to consider when selecting a PVC hose. A flexible PVC pipe is easy to install, especially in tight or cramped spaces. In addition, a flexible PVC hose pipe typically reduces pressure drops and increases the flow rate of the fluid. Therefore, it ultimately improves the overall performance of a system.

A too-rigid hose can be challenging to maneuver, while a too-flexible hose can kink and create safety hazards. Therefore, choosing the appropriate level of flexibility for the application is crucial. It ensures easy installation, efficient operation, and minimal risk of damage or failure.

Color

Color can be an essential consideration in industries where color coding is necessary for safety. PVC hoses are available in many colors, including clear, black, blue, green, yellow, and red. It is essential to choose a color that is appropriate for the intended use.

How to Select A Reputable PVC Hose Manufacturer

A reputable supplier or manufacturer ensures the quality of the product. They invest in research and development to create products that meet or exceed industry standards. They also utilize high-quality materials to manufacture flexible PVC pipes.

Choosing their products ensures increased lifespan and reduces the chance of premature failure. Therefore, choosing a reputable manufacturer is crucial for your project performance. Here are some essential steps to follow when selecting a supplier or manufacturer:

- Research and compare suppliers: Research potential manufacturers and compare them against each other. Look for suppliers with a solid reputation and experience in the industry.

- Look for industry certifications and standards: A reputable manufacturer should have industry certifications. International Organization for Standardization (ISO) and the American Petroleum Institute (API) are noteworthy. These certifications ensure that the product meets specific quality and safety standards.

- Check customer reviews and testimonials: Read customer reviews of the manufacturer. Look for feedback on the quality of the product, customer service, and overall experience.

Additionally, consider the supplier’s level of customer service and support. A reputable PVC hose manufacturer or supplier should provide prompt and efficient customer service. The service may include technical support and assistance in selecting suitable PVC hoses.

Summary

Choosing a suitable PVC hose is crucial to ensure the successful operation of any fluid transfer system. While selecting a proper PVC flexible hose, it is vital to consider the above factors. Failure to choose the appropriate flexible PVC pipe can result in severe consequences. You may face equipment failure, safety hazards, and costly downtime. In addition, it is equally important to choose a reputable supplier or manufacturer when purchasing flexible PVC pipes.

Rentone Hose is one of the most popular hose suppliers in the world. They follow international standards to meet the specifications from all over the world. They invest in research and development to manufacture high-quality products. Therefore, if you face any questions, contact their customer service team.