We must recognize the importance of PVC hoses in different world fields. These hoses play a crucial role in various industries. They provide a reliable transfer of fluids and materials. We may use them in agriculture, industrial facilities, chemical processing, and HVAC systems. Therefore, it is essential to learn the fundamentals of PVC hose and its different types.

PVC hoses are famous for their versatility, affordability, and resistance to corrosion and abrasion. It is a durable synthetic material designed to transport liquids, gases, and even solid materials. The properties of PVC make it ideal for many applications. It is a lighter and more economical hose than rubber. In many applications, PVC hoses have replaced rubber.

This article focuses on understanding PVC flexible hoses and their applications comprehensively. It also highlights the factors to consider when choosing the right one for specific needs. The article equips readers with essential knowledge about PVC hoses and their advantages. In addition, we will discuss the fundamental differences between PVC and polyurethane hoses. By the end of this article, readers will be able to make informed decisions when selecting the right product for their applications. They can determine the ideal specification that meets their specific requirements.

What is A PVC Hose

PVC hose stands for polyvinyl chloride hose. It is a PVC flexible hose made from a synthetic thermoplastic polymer. These hoses are ideal for transporting fluids, gases, and solid materials in various industries. There are multiple layers in the construction of PVC hose. The inner layer is typically made of PVC, and the reinforced layer can be made of other materials. The inner layer provides a smooth passage for the flow of substances. On the other hand, a reinforced layer adds increased strength and pressure resistance. Finally, the outer layer protects the hose from external factors like abrasion and chemicals.

The manufacturing process involves four primary steps:

- The PVC compounding step mixes the PVC resins with plasticizers, stabilizers, and other additives.

- The extrusion process melts and forms a continuous tube. The process cools the PVC hose to solidify and stabilize its shape.

- The reinforcement addition process adds necessary reinforcement layers. It may involve braiding, spiraling, or wrapping the reinforcement materials around the inner tube.

- The manufacturing process ends with curing and finishing steps.

Advantages of PVC Hose

- PVC hoses are highly flexible. They are easy to handle and install and provide maneuverability in various applications.

- These hoses exhibit good resistance to abrasion, impact, and tearing. It ensures a long service life even in demanding conditions.

- PVC hose is resistant to many chemicals. As a result, it is suitable for diverse industrial applications.

- PC flexible hose is resistant to weathering, UV radiation, and ozone. Therefore, it becomes a perfect choice for outdoor use.

- It is lightweight and a cost-effective solution than rubber hoses.

- The maintenance of PVC hose is simple.

Variety of PVC Hoses And Their Applications

PVC hose comes in various types, each designed to meet specific needs and applications. Each of these types provides unique properties ideal for a particular use. In the following, we have categorized PVC hose into six primary types. We will discuss their characteristics, specific uses, advantages, and limitations.

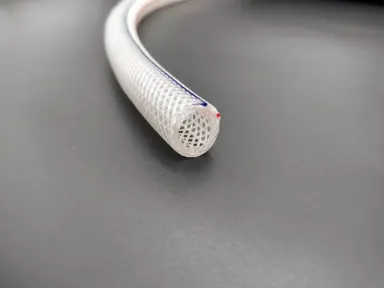

PVC Braided Hose

These PVC hoses come in a combination of PVC material and reinforcement braided textiles. It is typically made of high-quality synthetic fibers such as polyester or nylon. PVC braided hoses are prevalent in many applications. Plumbing, gardening, water supply systems, and industrial applications commonly use PVC braided hoses.

Pros

- PVC braided hose is versatile and can handle many applications

- It is incredibly durable and long-lasting.

- The braided reinforcement makes them durable and long-lasting.

- PVC braided hoses exhibit good resistance to various chemicals.

- Cost-effective solution.

Cons

- PVC braided hose has temperature limitations. It may not be suitable for extreme temperature applications.

- Extended exposure to UV radiation may degrade the outer PVC layer.

- Not ideal for certain chemicals

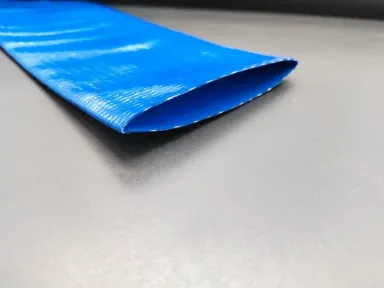

PVC Layflat Hose

As the name implies, PVC layflat hose is flat, and flexible made of PVC material. It comes with a unique construction method. It involves extruding PVC into a flat shape and then folding and bonding the edges. However, PVC layflat hose finds widespread applications in various industries. In agriculture, PVC layflat hose is essential for efficient irrigation systems. Additionally, it is suitable for dewatering operations. Some operations include draining excess water, flooded areas, or underground spaces.

Pros

- PVC layflat hose allows for compact storage and easy transportation.

- It is lightweight and makes it easy to handle and maneuver. You can quickly deploy a PVC layflat hose to a water source rapidly. It saves you time and effort during setup.

- PVC layflat hoses offer excellent flexibility. It enables convenient installation and movement around obstacles.

- It is also a cost-effective solution.

Cons

- PVC layflat hoses may not be suitable for high-pressure and high-temperature applications.

- It is vulnerable to abrasion, typically when dragging or rubbing against rough surfaces.

- Extended exposure to sunlight and UV radiation can degrade the outer PVC layer of the hose over time.

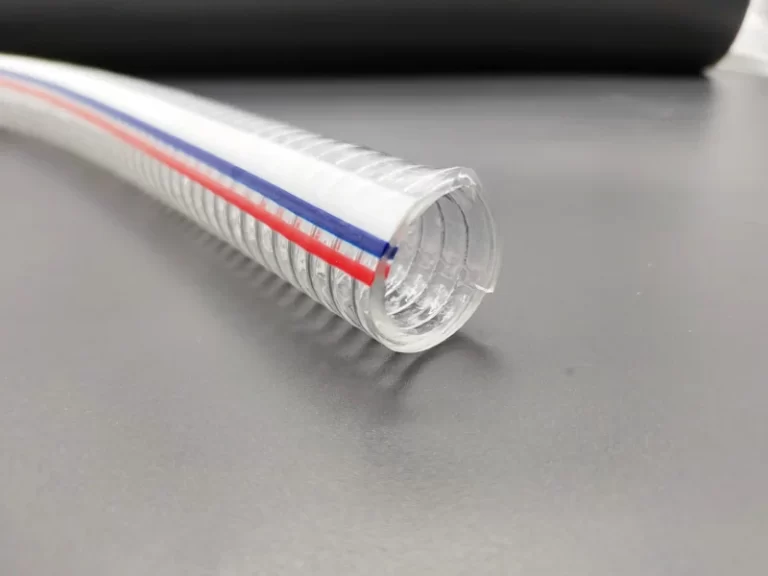

PVC Steel Wire Hose

PVC steel wire hose comes with a PVC tube, embedded steel wire helix, and a smooth PVC cover. The steel wire helix typically provides strength, flexibility, and stability to the hose. It is mainly found in construction, mining, and material handling applications.

Pros

- PVC steel wire hose is suitable for use as a vacuum straw. It has excellent suction capabilities. Therefore, it can efficiently handle suction tasks such as dewatering or material extraction.

- It is clean and transparent. As a result, it provides a visual inspection of the flow and detection of potential blockages.

- It is also a non-toxic material.

- PVC steel wire has scaling labeled on the hose.

- It can handle high-pressure applications. PVC steel wire hose also provides reliable fluid transfer under demanding conditions.

Cons

- PVC steel wire hose may kink if not appropriately handled. It affects the flow of fluids.

- It is not suitable for extreme temperature applications.

Reinforced PVC Hose

These PVC hoses come with a PVC inner tube, multiple layers of reinforcement, and a PVC or synthetic rubber outer cover. The outer surface protects the hose from abrasion, weathering, and external damage. Reinforced PVC hose suits pressurized or corrosive gas and liquids transfer applications. It is widely popular in machinery, coal mines, petroleum, and chemical industries.

Pros

- A reinforced PVC hose is ideal for high-pressure applications.

- Its sturdy structure ensures a long-lasting lifetime.

- PVC-reinforced hoses are also suitable for chemical processing applications.

Cons

- Not suitable for high-temperature applications

- It may not be ideal for certain chemicals

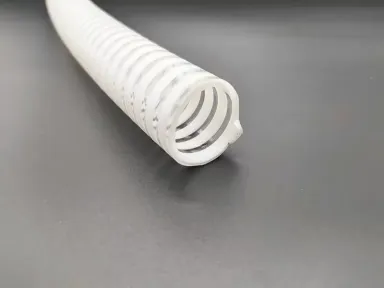

PVC Suction Hose

A PVC suction hose is ideal to withstand vacuum pressure. It has a PVC inner tube, a rigid spiral reinforcement, and a PVC or synthetic rubber outer cover. The spiral reinforcement provides structural integrity. It also prevents the hose from collapsing under vacuum or suction conditions. PVC suction hose is widely popular in wastewater management. It offers excellent service in transferring sewage, sludge, and other liquids with solids.

PVC suction hose is also prevalent in agricultural and marine operations. These hoses find application for irrigation, water pumping, and drainage systems. On the other hand, some marine applications include bilge pumping, water transfer, and handling of liquids and slurries.

Pros

- A PVC suction hose is ideal for handling suction or vacuum conditions.

- The rigid PVC spiral reinforcement provides structural strength to the hose. It also prevents collapse and maintains the integrity of the suction or vacuum system.

- PVC suction hose is also flexible, resistant to certain chemicals, and cost-effective.

Cons

- PVC suction hose may clog if you transfer fluids containing large particles or debris

- Not suitable for high-pressure applications

- Not suitable for high-temperature applications

PVC Garden Hose

These hoses are ideal for residential and commercial use. Their applications include gardening, outdoor cleaning, and general water supply. A PVC garden hose has a PVC inner tube, a polyester or nylon reinforcement layer, and a synthetic rubber outer cover. PVC garden hose is widely used for watering plants, lawns, and gardens in residential and commercial settings. These hoses are crucial in washing vehicles, decks, sidewalks, and outdoor furniture in outdoor cleaning. Moreover, PVC garden hoses can be used for general water supply purposes. Some of these applications include filling pools, ponds, or water containers.

Pros

- A PVC garden hose is lightweight and flexible. As a result, it is easy to handle, maneuver and store.

- It has a feature allowing easy attachment to sprinklers or other watering devices.

- It is indeed a cost-effective solution.

- PVC water hose is also versatile and resistant to weather.

Cons

- PVC garden hoses may have lower pressure ratings than other PVC hoses discussed above. As a result, it is not suitable for high-pressure applications.

- It is susceptible to kinking. It restricts water flow and requires manual straightening.

Conclusion

Throughout this article, we have explored the world of PVC hoses and their various types. We learned about PVC hoses’ composition, fundamental properties, and pros and cons. PVC hose is a better option than other hoses for specific applications. Although, these hoses are not suitable for high-temperature applications. In these cases, rubber hoses are the ideal option.

When choosing a PVC hose, it is crucial to consider the specific requirements of your application. Consider some essential factors like pressure, temperature, and environmental conditions. You can also consult with professionals or hose specialists who provide expert advice. You can also seek assistance in selecting the most suitable PVC hose.