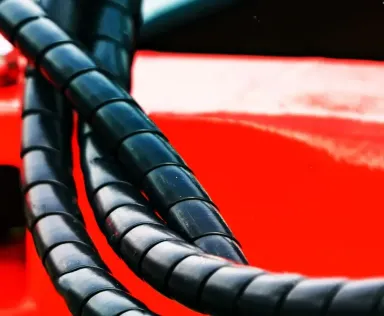

Hydraulic systems are an essential component used in machinery and industries. In this case, hydraulic hoses are crucial in transporting hydraulic fluids. These hydraulic fluids or oils typically use high pressure to transmit power and facilitate movement. From small machinery to giant industries, they all require specialized hydraulic hoses. These hoses are exposed to abrasion, harsh environments, and potential damage. Hydraulic hose spiral wrap protects them from external threats.

A hydraulic hose spiral wrap is a protective covering designed to protect hydraulic hoses from external hazards. The primary function of hydraulic hose spiral wrap is to extend the hose’s lifespan. We will know more about it later. Now, you can already guess the theme of today’s article.

This article aims to provide a comprehensive guide on hydraulic hose spiral wrap. It explores its benefits, production process, and the importance of choosing a suitable spiral wrap. The article highlights the significance of hydraulic hose spiral wrap and its proper utilization. By understanding these, readers can enhance hose protection in their hydraulic systems. In addition, they can also maximize equipment performance and improve overall operational efficiency.

Lastly, it presents the most reliable and trustworthy product for your application. You can navigate the products page by clicking the link attached to the product’s name.

What is A Hydraulic Hose Wrap Spiral Tubing?

The definition says a spiral wrap is a specialized protective covering designed to protect hydraulic hoses. It protects hoses from external hazards like abrasion, environmental factors, and potential damage. It is an essential component that ensures the durability and longevity of hydraulic systems.

The design and construction of a hydraulic hose spiral wrap are simple. It features a unique spiral shape that wraps around the hose in a coiled configuration. This shape provides flexibility and expandability. It enables easy installation. Besides, it can accommodate hoses of different diameters.

Moreover, the material used for the hydraulic hose protector spiral must be durable. It should resist abrasion, chemicals, UV rays, and other environmental factors. Some common materials include polyethylene, nylon, or polyester. These materials are highly flexible and robust. They are capable of withstanding conditions often encountered in hydraulic applications.

The primary function of a hydraulic hose spiral guard is to protect the hydraulic hose from various hazards. Manufacturers mainly focus on spiral hose protection against abrasion. In this case, the spiral wrap is a buffer between the hose and external surfaces. It reduces friction and prevents premature wear. It is important to note that abrasion occurs from rubbing against rough edges. In addition, the spiral wrap also shields hoses from harmful environmental elements. It provides a barrier against UV rays, which can cause degradation and premature aging of hoses.

Why Is Using Hydraulic Hose Spiral Wrap Essential?

We all know that hydraulic hoses operate in demanding environments. They face various risks and challenges. Besides, they face continuous pressure, temperatures, friction, impact, and contact with abrasive surfaces. These external factors create hose wear, degradation, and potential failure. You can only eliminate these problems if you can adequately protect them.

On the other hand, the consequence of hydraulic hose failure can be significant. Hose failure typically requires costly repairs. In addition, you should halt your operation for repairs or hose replacement. This downtime brings lost productivity, missed deadlines, and delays in project completion. Moreover, the sudden release of pressurized fluids from a failed hose can pose safety hazards to personnel. It could cause injuries or accidents.

Furthermore, hose failure damages the other components of a hydraulic system. Valves, pumps, and cylinders can be affected by this situation. As a result, it requires additional repair and replacement costs. The overall financial impact of hose failure goes beyond the repair expenses. It also affects the profitability and efficiency of the entire operation.

Therefore, using hydraulic spiral wrap prevents the potential consequences of hose failure. In this case, Spiral wrap is a protective shield that reduces the risk of hose abrasion, cuts, and other damage. Therefore, implementing these preventive measures enhances safety and reduces downtime. Ultimately, it optimizes the performance and longevity of their hydraulic systems.

Benefits of Using Hydraulic Hose Spiral Wrap

Hydraulic hose spiral wrap is a crucial component in every hydraulic system. We already know why we should use a spiral hydraulic hose protector. It provides a reliable and versatile solution for safeguarding from various risks. It also ensures the optimal performance of a system. Here are some benefits you can get from using spiral wrap.

- Protection Against External Factors: Spiral wrap protects the hose from external factors. It is a protective barrier against UV rays, chemicals, moisture, and extreme temperatures. Protecting hoses with spiral wrap prevents wear, degradation, and damage.

- Easy Installation: The flexible hydraulic hose spiral wrap provides hassle-free installation. You can quickly wrap around hydraulic hoses without requiring specialized tools. It saves time and ensures efficient installation.

- Improved Hose Organization And Identification: Spiral wraps organize multiple hoses. It keeps the hydraulic hoses neatly bundled together. As a result, they minimize the risk of interference with other components. Besides, hydraulic hose spiral wraps provide color-coded options for easy identification.

- Increased Safety Measures: Spiral wraps protect hoses from wear, abrasion, and damage. Therefore, they reduce the risk of hydraulic failure. Subsequently, they grow safety measures for operators.

- Environmentally Friendly: Hydraulic hose spiral wrap materials are reusable and recyclable. It contributes to environmental sustainability.

- Bespoke Options: Hydraulic hose spiral wrap often offers customization options. It allows operators to choose the right size, material, and color.

The Production Process of Hydraulic Hose Spiral Wrap

The production process of hydraulic hose spiral wrap is simple and easy. Unlike typical extrusion, this process adds spiraling steps to create flexible spiral wraps. Each step is vital in achieving high-quality spiral wraps from the material section to the final product.

Material Selection à Extrusion à Spiraling à Cooling à Storing

The process begins with material selection. Manufacturers prefer polyethylene, nylon, or polyester to create hydraulic hose protective wraps. In this case, the selection process depends on the flexibility and strength of the final product. It is also necessary to consider resistance properties against various external factors.

Next, the process undergoes an extrusion process. It involves melting the polymer and forcing it through a die to create a continuous spiral-shaped profile. After extrusion, the spiraling step carefully aligns the extruded profile to form the spiral pattern. Once the spiraling process is complete, the newly formed spiral wrap can cool. Cooling is essential to stabilize the shape and dimensions of the wrap. Finally, the spiral wrap is carefully stored to prevent damage or deformation.

Throughout the production process, you should implement quality control measures and inspections. It ensures that the spiral wraps meet the required standards and specifications.

How to Choose The Right Hydraulic Hose Spiral Wraps

Choosing the right product is necessary to ensure adequate spiral guard hose protection. In addition, the right spiral wraps optimize the performance of your hydraulic system. First, asses the requirements of your application. In this case, consider factors such as the type of hydraulic system and the environment in which it will operate. You can also view the potential hazards the hoses may encounter.

Second, measure the hose diameter and length. In this case, select the appropriate size of the spiral wrap. The right product ensures a perfect fit and optimal coverage. Third, consider the temperature and pressure ratings. Choose a material that can withstand certain temperatures and pressure levels within your system.

Fourth, check the compatibility of spiral wrap material with the hydraulic fluid used in your system. Some hydraulic fluids may have corrosive compatibility requirements. Fifth, assess additional features like UV, chemical resistance, color-coding, and flame retardant properties. Finally, consult with reputable suppliers. In this case, you can seek advice from a Rentone hose specialist. They make clear understanding and provide the best service possible.

Rentonehose PP Spiral Guard

Rentonehose PP spiral guard is a top-quality protective covering. It offers excellent abrasion resistance while maintaining an attractive appearance. It provides an affordable and convenient solution to safeguard hydraulic hoses, cables, and wires. PP Spiral Guard effectively prevents premature wear and tear. Rentonehose PP Spiral guard is designed to withstand high and low temperatures. As a result, they exhibit remarkable toughness, elasticity, and resistance to deformation.

Rentonehose PP Spiral guards come in a wide range of sizes and models. From HPG-PPSG-8 to HPG-PPSG-200, you can choose the appropriate size for your hydraulic hose. The strength of these spiral wraps is 20 MPa at ambient temperatures. Besides, they provide a wide range of tolerable temperatures ranging from -50℃ to +100℃ (-60℉ to +210).

Summary

Hose failure is a common threat for all hydraulic system operators. Hose failure mainly occurs from external hazards. Here, the best solution to mitigate the problem is to use spiral wraps. A hydraulic hose wrap is necessary to protect the hydraulic hose from external hazards. Spiral wraps are made of various materials based on different circumstances.

Hydraulic hose spiral wraps provide a wide range of benefits. It is easy to install. It protects your hydraulic hose from all types of external hazards. Besides, they are environmentally friendly and offer customization options.

The manufacturing process of hydraulic hose spiral wraps is simple. After the extrusion step, the spiraling process is unique and needs careful operation. After spiraling, the process follows the cooling and storing step like other extrusion processes.

Rentonehose is one of the world’s most popular hydraulic hose manufacturers. They produce high-quality hydraulic hose spiral wraps. Rentonehose PP spiral guard is one of their most incredible creation. It comes in a wide range of sizes and models. Based on your application, you can choose the most appropriate model. Contact their customer support team if you have questions about their spiral hoses. They keep one of the best customer service teams in the world. Therefore, you can quickly contact them and get all your answers.