A high-power hydraulic hose is one of the most critical components in a high-pressure hydraulic system. Its main job is to transfer high power to the whole system. It’s like the blood vessels in your body. One wrong choice may create accidents and damage your system.

What is a High-Pressure Hydraulic Hose?

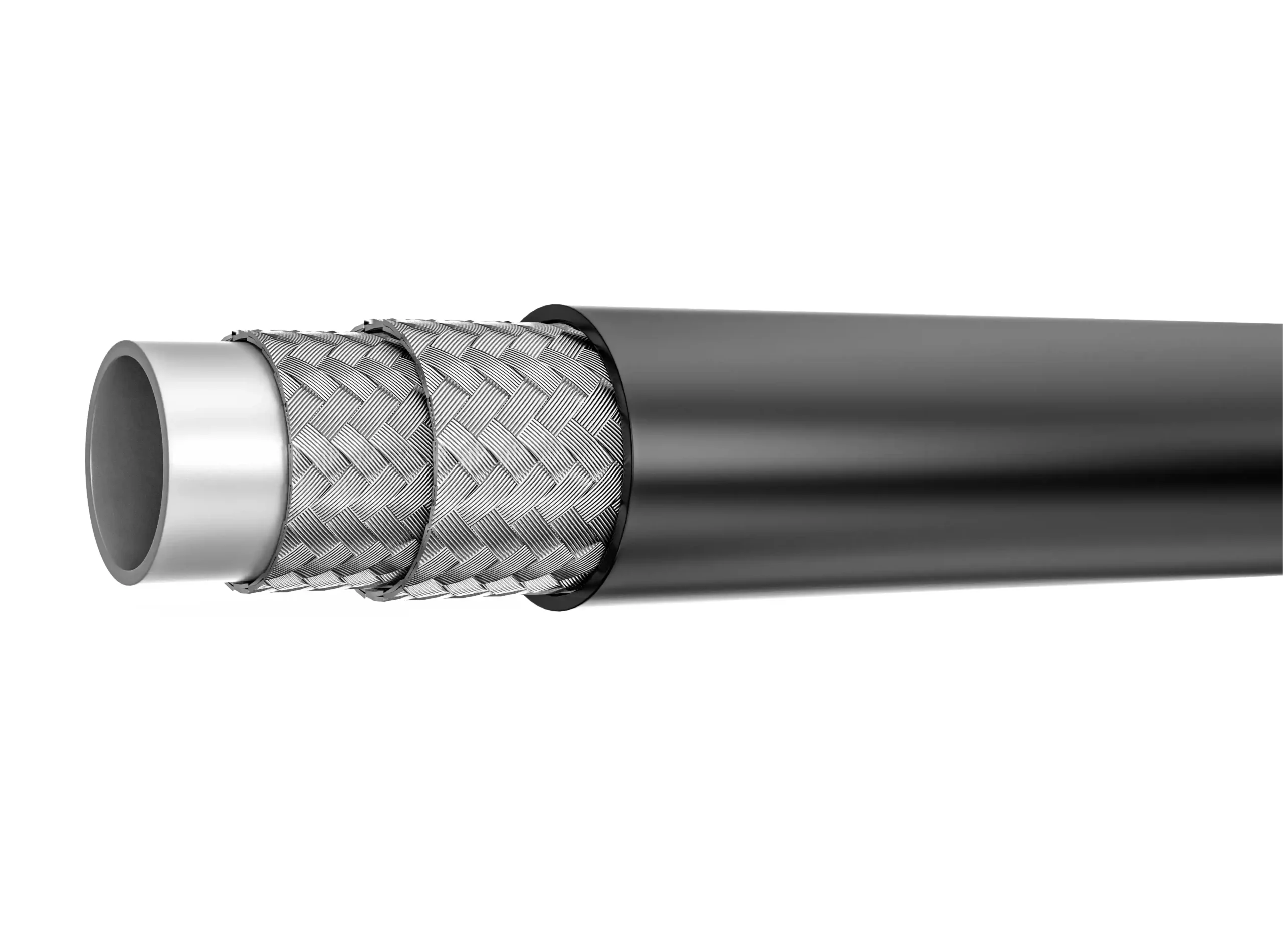

A hydraulic hose is a flexible tube that transports water or oil. A high-pressure one is mostly about extreme pressure applications, usually more than 1000PSI. It is strengthened with steel wire or synthetic materials to withstand this pressure. You may often find it connected with pumps, valves, and cylinders.

There are many different types of high-pressure hydraulic hoses. If you consider how they are made, there are five main types. On the other hand, there are two types of steel wire reinforcement: spiral and braided. However, if you consider the types based on standards, there are four types: SAE, ISO, DIN, and EN.

High-pressure hydraulic hoses are widely used in many fields. However, they are primarily used in hydraulic machinery. Typical examples include cranes, excavators, and tractors to control heavy loads. You may also find its use in many power hydraulic presses and lifting systems. In automotive, hydraulic pressure hoses are used in the braking systems.

Characteristics of a High-Pressure Hydraulic Hose

When you take a high-pressure hydraulic hose, how do you identify it? You can check the labeling, inspect the fittings, and check how they are made. You can also check the flexibility, bending radius, and standards. Here are some key characteristics of a high-pressure hydraulic hose:

- A hydraulic hose of higher pressure should be able to bear a certain pressure. It will be pertinent to discuss the working and burst pressures here. In general, they have to be 1:4 or 1:3.

- These hoses can operate under pressures from as low as 1000 PSI up to and beyond 10000 PSI. Depending on the size and type of the hose, you may also get a higher pressure rating.

- The construction of a high-pressure hydraulic hose pipe must be reinforced with steel or synthetic material.

- The outer cover of the hose must be made of thermoplastic or high-quality rubber. This material is resistant to weather and wear and tear.

- The inside tube, on the other hand, must be oil-resistant. NBR rubber is usually used because it doesn’t absorb petroleum oil.

How Do You Select a High-Pressure Hydraulic Hose?

When selecting a hydraulic hose, you must be careful. However, if it involves high pressure, you must be doubly cautious. Why? High pressure may lead to workers’ safety risks, equipment damage, and costly repairs. This section will highlight six crucial factors when selecting a high-pressure hydraulic hose.

Factor #1. High-Pressure Hydraulic Hose Pressure Rating Safety Factor

Safety is among the most important considerations when choosing a high-pressure hydraulic hose. A hose safety factor is the ratio between the working and burst pressure. According to the SAE J517 Standard, this safety factor is 4:1. However, a 3:1 ratio may also be found for several hydraulic hoses.

To understand the safety factor, you should also be familiar with two important terms. First, working pressure is the maximum pressure of the hose during regular transfer. Second, burst pressure is the maximum pressure a hose can withstand before it splits. The relationship between burst and working pressure is termed a safety factor.

A safety factor of 4:1 means the burst pressure should be four times greater than the working pressure. For example, if your high-pressure hydraulic hose pipe has a working pressure of 100 PSI, the burst pressure must be 400 PSI. As to 3:1, the burst pressure should be equal to 300 PSI.

Why should you care for this factor? There are many reasons. First, the safety factor keeps the hose from breaking and keeps workers safe. Second, it extends the lifespan of your hydraulic pressure hose. Third, it can resist impact pressure and avoid system downtime.

Factor #2. High-pressure Hydraulic Hose Material

The hose material is another important factor you should consider right after the safety factor. It has a huge effect on how well your hose works. In particular, it decides your hose’s strength, flexibility, and longevity. Some common types of materials used in high-pressure hydraulic hoses are:

- Synthetic Rubber: Different kinds of synthetic rubber may be used in factories to make hydraulic hoses. Each type has unique benefits, but NBR is the best for high-pressure hoses. However, synthetic rubber can offer you the highest bending radius. You can use these hoses to install based on your convenience. As usual, they can resist high heat, oil, and abrasion.

- Thermoplastic is generally lighter than synthetic rubber. Because of this, thermoplastic is widely used in many applications. It is also resistant to high heat.

- Steel Reinforcement often comes with a base material (mainly plastic or rubber). What it does is add extra strength to the hose. Because of this, your hydraulic hose can handle more pressure.

- PTFE (Teflon) is highly resistant to chemicals and extreme temperatures. It is mainly used in high-pressure systems involving chemicals.

What makes the hose material a significant factor in choosing high-pressure hoses? Wrong material often creates leaks, cracks, and bursts. These problems create safety risks and costly repairs. There’s another reason why the correct material is essential: Durability. A suitable hose material will last longer and work better.

Factor #3. High-Pressure Hydraulic Hose Construction and Size

A high-pressure hydraulic hose may have various constructions. This variety is mainly due to the fluid transfer type and pressure level. Two types of construction are the most widely used: spiral and braided.

Both of these structures provide high-tensile steel wire. They can be made up of one or more layers. Pressure levels usually determine the number of layers. However, this layering style might be different from type to type.

As the name suggests, spiral hoses have spiraled steel wire, while braided ones have braided steel wire. Although their layering style is different, they have the same purposes. Both forms provide fabulous strength and flexibility.

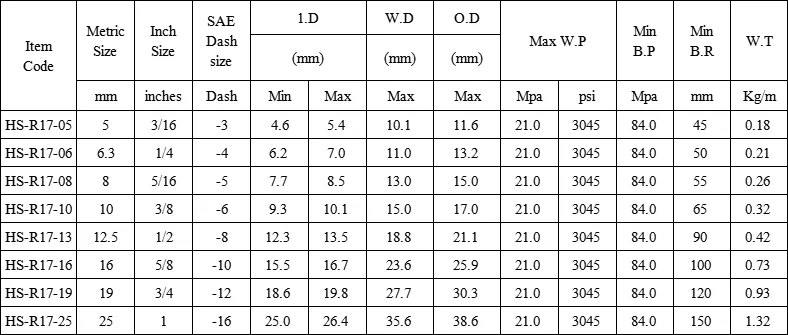

Another critical factor that you should consider is the size. A high-pressure hydraulic hose always comes with a standard sizing. The standards typically depend on the country and the national standards. You learn more about it in the last pointer.

However, the size includes the inner and outer diameter, lengths, and thicknesses. Why is the size critical for high-pressure hydraulic hoses? The right size can help you choose the right hydraulic hose fittings for your project. Besides, you must select the length based on the distance between components in the system. Consider the bending radius if the hose is longer than it should be.

Factor #4. High-Pressure Hose Fittings

A high-pressure hydraulic hose also requires matching hydraulic fittings at both ends. It plays an essential role in the entire system. So, you should keep this in mind while making your selection.

High-pressure hose fittings must be able to handle both working and burst pressure. There are generally a variety of types. However, some notable types common in the market are crimped, threaded, flare, and O-ring fittings.

This wide variety comes mainly from the use of different types of hydraulic connections. Each is designed to withstand a specific pressure level and to particular connections. Their primary function is to ensure the hose is correctly connected to the primary system.

Factor #5. High-Pressure Hydraulic Hose Bend Radius

The bend radius is also a critical part of every high-pressure hydraulic hose. It is one of the main reasons for the pressure drop in your system. Therefore, experts always recommend reducing the bend radius as much as possible. Yet, high-quality hoses, like those from Rentone Hose, can effectively endure this pressure drop.

If you bend the hose very tightly, it might weaken and break before it should. To get around these problems, try to follow the manufacturer’s bend radius instructions. This is very important for hydraulic devices that use high pressure. However, tight turns can be avoided by routing and setting up the hoses correctly.

Factor #6. High-Pressure Hydraulic Hose Standards and Certifications

In the modern world, several standards are used to make hydraulic hoses. The popular standards are SAE (Society of Automotive Engineers), ISO, and EN. You may also find the use of DIN (Deutsches Institut fur Normung).

Before choosing a standard, always know your project’s needs. With this information, you can identify the standard and, thus, the size you require for your project.

Standards and certifications make things safe and well-made. They also make the hoses widely available during repair. High-pressure hydraulic devices have to work in extreme conditions. If you don’t follow the proper rules, your hose could break, causing crashes or leading to expensive repairs. However, certified hoses undergo many tests to ensure they will work well.

Get in Touch With Us!

If you have any queries about high-power hydraulic hoses, you are welcome to discuss them with our customer support team. Rentone Hose is always keen on their customer’s responses all the time. If you wish to see the particulars of our hydraulic hoses, you can conveniently go to our product page. W