An appropriate hose is necessary for systems with adequate performance and durability. It is essential in various industrial and commercial settings. PVC tubing is one of these sectors’ most popular plastic hoses. On the other hand, polyurethane tubing is also prevalent in some applications. People with less experience face trouble choosing suitable tubing for their project. These two tubing offer distinct advantages and properties to suit specific needs.

Both PVC tubing and polyurethane tubing have their unique strengths. This characteristic makes them indispensable components in various industrial and commercial applications. Understanding their distinct properties and advantages is essential in making an informed decision. It is necessary when choosing the correct tubing material for specific applications. The right choice ensures optimal performance and achieving long-term reliability.

This article aims to prove the fundamentals of these two rubber tubings. It highlights the overview of their properties, applications, and limitations. In addition, we can also learn their similarities and dissimilarities in the later sections. By gathering these informative resources, one can make an informed decision when choosing the plastic hose. We can ensure that the plastic hose we select meets the industry and application standards.

PVC Tubing vs. Polyurethane Tubing

Regarding plastic tubing, PVC and PU materials are the most popular raw materials for hose manufacturing. Both Polyurethane and PVC are thermoplastics. Both PVC and PU are moldable at higher temperatures. When cooling, they solidify again. The manufacturers can mold them into any shape, including tubing. They are applicable in various applications based on their physical and material properties. But, one can hold more benefits than the other in some uses in many situations.

While both PVC and Polyurethane are popular materials, they have distinct characteristics. Let’s explore the nature of these two substances and examine their commonalities and disparities. Additionally, we will determine which material is more suitable for tubing manufacturing. In the following article, we aim to address all these inquiries comprehensively.

What is PVC Tubing?

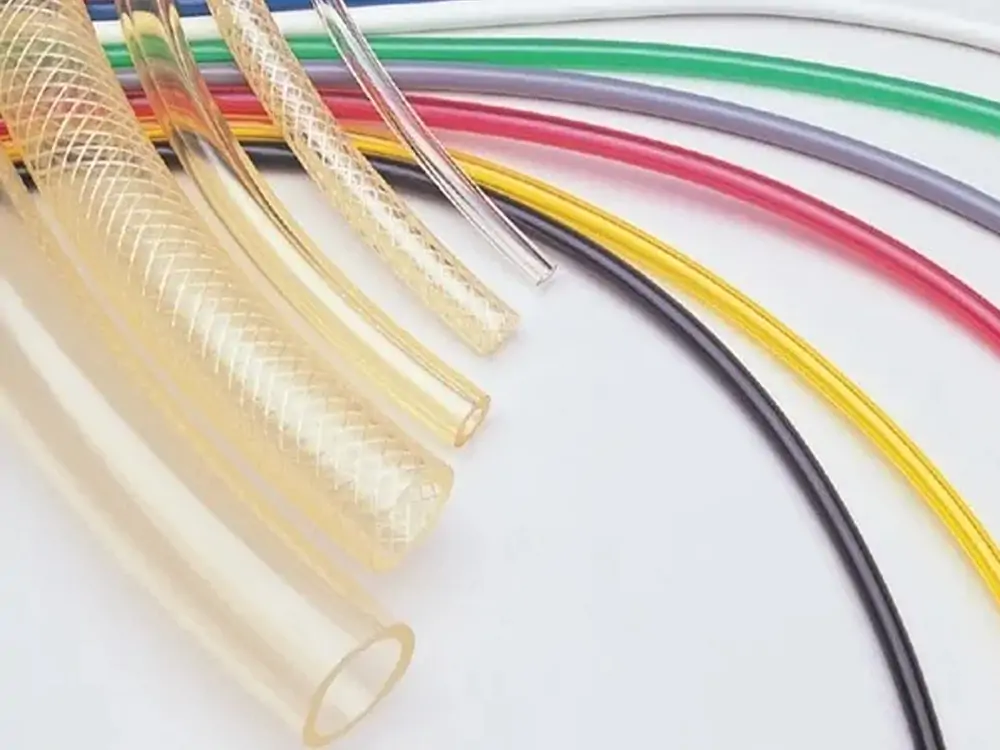

PVC stands for Polyvinyl Chloride and is famous for its flexibility. It is a synthetic polymer with a wide range of applications due to its versatile properties. PVC tubing comes from an extrusion process where the PVC material turns into tubular shapes. They come in various diameters and thicknesses. PVC products have an extensive range of applications compared to other plastic tube pipe materials. However, plastic piping products can only fulfill some application requirements universally.

The flexible PVC pipe can bend and adapt to different shapes and contours. As a result, they are ideal for applications where maneuverability is required. Some PVC tubing variants are transparent. This characteristic allows them to inspect the fluid flowing through the tube quickly. Besides, PVC tubing has a smooth inner surface that facilitates fluid flow. It also minimizes the risk of blockages.

PVC tubing exhibits excellent resistance to a wide range of chemicals. As a result, these plastic hoses are suitable for transporting various corrosive substances. They have good tensile strength, approximately 52 MPa. So they can withstand pressure and stretching forces during use. Besides, PVC tubing also provides a broad temperature range. They are lightweight, making it easy to handle and install. PVC tubing requires less labor and reduced transportation costs.

Applications

PVC tubing can be used in various applications due to its physical, chemical, and material properties. Here are some of the most prevalent applications for PVC tubing.

- Water transport: PVC tubing is commonly used for conveying water in various applications. Some uses include irrigation, water supply lines, and drainage systems. Besides, we may also find them in aquariums and aquatic systems.

- Medical and healthcare: PVC tubing is also prevalent in medical devices. Some typical applications include Intravenous (IV) lines, oxygen delivery systems, and catheters.

- Chemical transfer: PVC tubing provides excellent chemical resistance properties. We may see these tubings in many industrial settings. It is also popular in the food and beverage industry.

- Pneumatic systems: PVC tubing is used to transport compressed air or gases in the pneumatic systems.

Limitations Over PU Tubing

Although PVC tubing provides a wide range of benefits, it has limitations over PU tubing. Here are some limitations we may find from PVC tubing:

- PVC tubing has a relatively narrow temperature range compared to PU tubing. It might become brittle at low temperatures and soften at high temperatures. In these cases, threaded plastic pipes accommodate various temperature ranges.

- PVC is more susceptible to UV degradation. The exposure causes it to become brittle and discolored.

- It may not be suitable for certain aggressive chemicals. These chemicals may cause degradation or damage to the tubing.

- PVC tubing may contain plasticizers to increase flexibility. Over time, these plasticizers can leach out. Ultimately, it reduces flexibility and potential contamination of the fluid being transported.

What is Polyurethane Tubing?

Polyurethane tubing is also famous as a PU hose. It is a synthetic polymer known for its flexibility, toughness, and resilience. Polyurethane pipe comes from the extrusion process, where the molten PU material turns into a tubular shape. It comes with various diameters and wall thicknesses. It also provides a versatile and durable tubing solution.

Polyurethane tubing is also flexible, like PVC. This flexibility allows the tubing to bend and stretch easily without kinking or deforming. PU tubing exhibits exceptional resistance to abrasion. As a result, they are highly suitable for applications involving wear, friction, or impact. It also has good tear strength. So, It provides resistance against damage or tearing during installation and usage.

Polyurethane tubing can withstand a wide temperature range, from -80F to 200F. As a result, PU tubings are ideal for both high and low-temperature applications. It also has good resistance to many common chemicals. However, it may not be suitable for certain aggressive substances, which may cause degradation or swelling. It also has moisture resistance capabilities. Like flexible PVC tubing, it is lightweight and reduces its weight in applications.

Applications

Due to PU tubing’s unique properties, we can also find this product in various applications. Here are some popular applications:

- Pneumatic systems: PU tubing is widely used in pneumatic systems. It is typically used for air and gas transport due to its flexibility and resilience.

- Robotics and automation: PU tubing is prevalent in robotic applications. These applications need smooth movement and precise positioning.

- Automotive industry: polyurethane tubing is also prevalent in automotive applications. Some applications include fuel lines, brake systems, and air conditioning.

- Medical devices: PU tubing has applications in medical equipment, too. Like PVC tubing, we can also find Pu tubing in catheters, oxygen delivery systems, and blood pressure monitoring.

- Paint and coating equipment: PU tubing can be used in fluid transfer and distribution applications. Pain and coating equipment typically use this type of tube.

- Fluid transfer: PU tubing is also used for transferring various fluids like chemicals, water, and oils. Usually, we can find it in industrial processes.

Limitations Over PVC Tubing

Although PU tubing provides many benefits, it also has some limitations. Here are some restrictions we may find if we choose PU tubing for our applications:

- PU tubing is generally more expensive than PVC tubing. As a result, if you are looking for a budgeted option, something other than this type may be suitable.

- It may be unsuitable for highly aggressive chemicals like strong acids and bases.

- Some formulations of polyurethane tubing may have limited flame resistance. As a result, it may not be suitable for specific fire safety applications.

- Polyurethane recycling can be more challenging compared to PVC tubing. It limits the eco-friendliness of the product.

PVC vs. Polyurethane: Similarities

PVC and polyurethane are two widely used tubing materials with several similarities. Both exhibit good chemical resistance, flexibility, and durability. As a result, they became popular choices for fluid transport in various industries.

- Both are flexible tubing materials.

- PVC and PU tubing provide excellent chemical resistance properties.

- They are suitable for fluid transportation

- Both these tubings are popular in a wide range of applications.

- They are incredibly lightweight and easy to handle.

- PVC and PU tubing are not suitable for hydraulic systems. But they are popular in pneumatic solutions.

- They are durable and resistant to wear.

PVC vs. Polyurethane: Differences

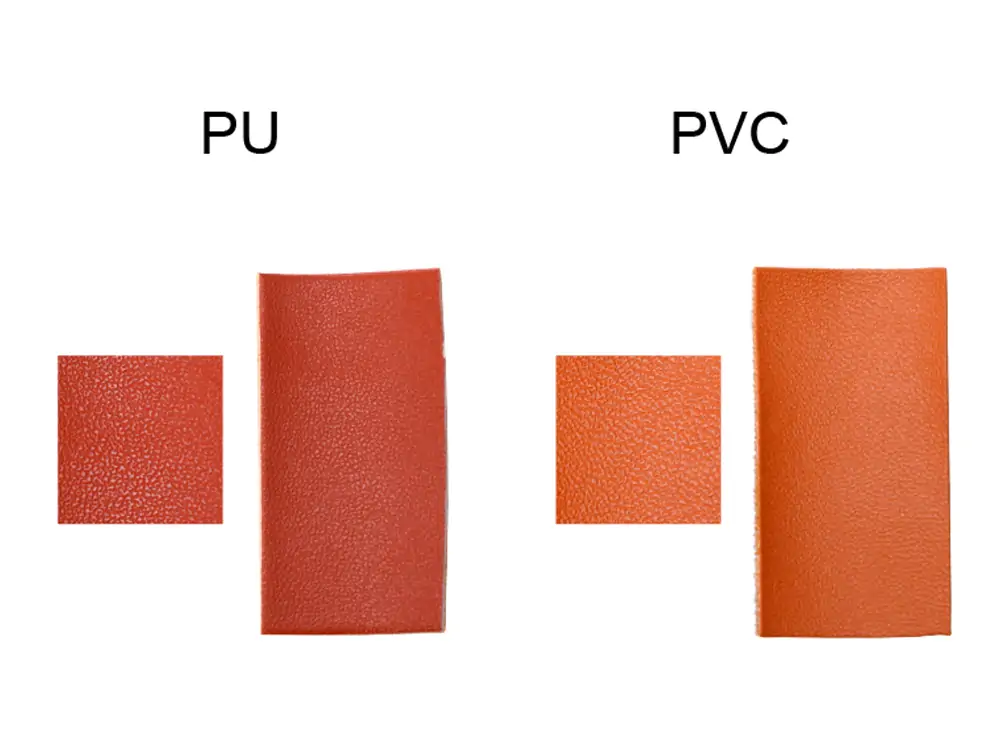

While PVC and polyurethane share some similarities, they have distinct differences. These differences set them apart as tubing materials. These variations include flexibility, temperature range, UV resistance, and cost. These factors significantly impact their suitability for specific applications in various industries.

| Content | PVC tubing | Polyurethane tubing |

| Composition | Made from Polyvinyl chloride | Made from Polyurethane tubing |

| Flexibility | Generally less flexible than PU tubing | More flexible than PVC tubing |

| Temperature Range | Narrower Range | Wide Range |

| UV resistant | May degrade in sunlight | More UV resistant |

| Chemical resistance | Good resistance to most chemicals | Good resistance to certain chemicals |

| Cost | Cheap | Expensive |

| Recycling | Easy to recycle | Difficult to recycle |

Conclusion

This article explored the properties and applications of PVC and polyurethane tubing. PVC offers good chemical resistance and is affordable. As a result, they are commonly used in plumbing, irrigation, and medical applications. On the other hand, PU tubing boasts high flexibility and abrasion resistance. It finds applications in pneumatic systems, robotics, and fluid transfer. Both materials are versatile solutions across various industries. In addition, it meets diverse fluid transport needs.

The choice between PVC and polyurethane tubing hinges on the unique requirements of each application. PVC suits applications where chemical resistance, affordability, and electrical insulation are vital. On the other hand, PU is ideal for applications demanding high flexibility and a broader temperature range.