Hydraulic and pneumatic systems are often used in manufacturing industries for distinct purposes. Air hoses are a crucial element of a pneumatic system. These air hoses find many applications across various sectors in the modern industrial landscape. The types of air hoses may vary based on different applications and pneumatic systems.

We all are familiar with air compressors. It’s a typical pressurized air compressing and storing machine used in automotive repair shops. If you observe this machine, you will find a rubber tube typically carries pressurized air. Similar applications can be observed in other applications. For example, in the manufacturing industry, pneumatic systems are used in assembly processes. It helps in gripping, positioning, or even moving components.

We can realize that varying types of air hoses are essential in manufacturing, construction, automobiles, and more. This versatility & extensive use of different types of hoses make them an important topic to discuss. Many customers need help choosing suitable types of air hoses. Therefore, understanding the fundamentals of air hoses is necessary.

With this aim, we have brought you this fantastic guide on different types of air hoses. We will talk about their distinct features and applications. In addition, we will discuss different types of fittings or connectors used during installation. Ultimately, we will learn how to choose the suitable types of air hoses for your project. Let’s get started.

What Is an Air Hose?

An air hose is a flexible tube, just like a hydraulic hose. But it is specially designed to carry compressed air from a compressor to pneumatic tools. They are typically made of rubber, PVC, or metal-reinforced materials. Well, air hoses come in various lengths & diameters. It depends on the suitability of different applications. We have realized that they are popular in manufacturing, construction, and vehicle maintenance.

While comparing hydraulic hoses with air hoses, we can observe differences. Their primary difference is the conveying materials, pressure levels, and construction materials. However, they are both essential for different applications. Check out the following table to understand the difference between hydraulic and air hoses.

| Criteria | Air Hoses | Hydraulic Hoses |

| Conveyed Fluid | Compressed air | Hydraulic fluids, mainly oil |

| Pressure levels | Compared to hydraulic hoses, air hoses offer low-pressure levels. It’s around 300 – 500 PSI. | Hydraulic hoses can withstand larger pressure up to 5000 PSI. |

| Construction Material | Rubber, PVC, reinforced metal | Rubber, thermoplastic, or metal |

| Flexibility | Air hoses are generally more flexible than hydraulic hoses. | Hydraulic hoses may be rigid or flexible. It depends on the distinct types. |

| Temperature Range | Wide temperature ranges (depending on material) | They also come with a wide range. It depends on the type of hydraulic hoses and the applications. |

| Applications | Pneumatic tools, air compressors | Hydraulic machinery, lifts, and heavy equipment |

Types Of Air Hoses

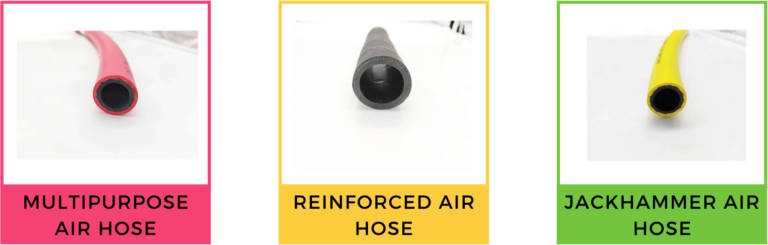

As said, different types of air hoses may appear based on various criteria. These may include purpose, construction, pressure, temperature, and applications. It is important to note that each air hose type may be destined for unique applications. However, typically, we find four significant types of air hoses in various pneumatic systems.

Type 1: Standard Air Hose

These types of air hoses are usually general-purpose pneumatic pipes. We can often see them near us. The primary purpose of these air hoses is to convey general-purpose air from a pneumatic system to various tools. The construction materials used for these air hoses are rubber, PVC, or hybris. They are moderately flexible than retractable air hoses.

A typical example can be observed. We can consider the multipurpose 300 PSI air hose from the Rentone Hose brand. They are made of natural rubber & SBR synthetic rubber blended. They can withstand average temperature ranges of -20 °C – +70°C (- 4°F – +158°F) and the highest 300 PSI of pressure.

Besides, they provide moderate pressure levels. They are relatively durable in various applications. They have extensive applications in general pneumatic tasks, such as air tools and inflation. In addition, they come with a simple design with no additional features. Note that the temperature range may vary based on different material composition. Finally, they offer a cost-effective solution that is versatile for various applications.

Type 2: Retractable Air Hose

A retractable air hose offers a unique mechanism that allows it to automatically retract or coil back into a compact form after use. Typically, these hoses come in a reel that can be mounted on walls or ceilings for convenient storage. So, a motor or spring-loaded system can facilitate the retractable feature. These types of air hoses aim to ensure that the hose remains organized and tangle-free.

So, to provide this feature, a retractable air hose must ensure flexibility and proper material selection. Popular materials used for these types of air hoses are rubber and PVC. These air hoses are ideal for garages and workshop settings. They are suitable for places where space is a prime concern.

Although, these air hoses might not be suitable for high-pressure or high-temperature applications. Still, they are durable for moderate pressure and temperature applications.

Type 3: High-Pressure Air Hose

A high-pressure air hose is a reinforced air hose fortified with additional material layers. The purpose of this reinforcement is to enhance strength, durability, and resistance to pressure. These hoses usually offer higher levels of stress. As a result, they are highly suitable for applications that demand robust performance and extended service life.

A typical example can be observed. Consider the Rentone Hose air hose models IH-ARW – 005 to IH-ARW – 102. This air hose has numerous high-tensile synthetic rubber reinforcement layers. It typically offers a temperature range from -40℃- 70℃ (-40℉- +158℉). Furthermore, it has a pressure range of 300 PSI to 1200 PSI. Besides, we can consider the Rentone Hose models IH-JA-019 and IH-JA-025 Jackhammer air hoses. Even though it is not a reinforced air hose, it is a high-pressure air hose. These air hoses typically offer lower pressure levels than reinforced air hoses. Their maximum working pressure is 300 PSI, while their braking pressure is 900 PSI.

A high-pressure air hose features various advantages. They come with an abrasion-resistant cover- and oil-mist-resistant tube. They are highly flexible and oxidation-resistant. In addition, they also feature weather resistance, anti-aging, and long service life. Typical applications can be found in mining, construction, shipyards, agriculture, etc.

Type 4: Heat Resistant Air Hoses

A heat-resistant air hose is also a type of reinforced air hose. These are some specialized types of air hoses. As the name implies, heat-resistant air hoses are ideal for applications with high temperatures. So, we can see these types of air hoses in foundries, steel mills, or applications near hot machinery. Therefore, the materials used in these types of air hoses are EPDM, silicone, or other specialized materials. You know these materials are excellent for thermal stability. They also ensure that the hose remains functional even in extreme heat.

Moreover, design considerations may include reinforced layers to maintain structural integrity. Additionally, the hoses may feature heat-reflective or insulating properties in their outer layers. You know it minimizes heat absorption. It aims to prevent deformation and cracking when exposed to prolonged high temperatures.

How to Choose the Right Types of Air Hoses

We can realize that air hoses may come in various types and sizes. Therefore, we cannot randomly choose a kind that may lead to severe consequences or safety hazards. However, selecting the suitable types of air hoses involves several considerations. This observation is necessary to ensure your chosen type meets the specific requirements.

- Projected Application: First, evaluate the application’s environment. Does it involve extreme temperature or high stress? Does it involve use in outdoor applications? Does your application area concern storage? So, it’s essential to evaluate the projected application carefully. It determines the primary types of air hoses suitable for your application.

- Pressure Range: Determine the required pressure rating for the application. It helps you ensure the selected hose can safely handle the maximum pressure of the pneumatic system.

- Temperature Range: It is also necessary to evaluate the temperature conditions of the environment. For instance, opt for heat-resistant hoses if working in high-temperature settings. You should also know if your application involves a low-temperature environment.

- Length: Choose the hose length based on the distance. Calculate the distance between your pneumatic system and the intended application point. A little more considerable length is recommended in case you need adjustment.

- Diameter: Select the hose diameter by airflow requirements. The right air hose type ensures an adequate volume of air required to deliver optimal performance.

Summary

Let’s wrap everything up! In this comprehensive guide, we’ve covered different types of air hoses available. We have learned four significant types of air hoses. They are standard air hoses, retractable air hoses, high-pressure air hoses, and high-temperature air hoses. Although, we can categorize high-pressure and high-temperature air hoses into reinforced air hoses. Sometimes, heat-resistant air hoses may not come with a reinforced structure.

So, when choosing the right type, we should consider five major factors. They are application settings, pressure rating, temperature range, appropriate lengths, and diameter. Above all, this article can help our readers make informed decisions.