Hydraulics is a fantastic technology that allows you to deal with heavy loads simply and efficiently. This work is typically done within a hydraulic system, and hoses are an indispensable part of it. Consequently, the hydraulic hose pressure rating is the most critical factor for these systems.

When you go deep into the world of hydraulics, you will find various terms. Hydraulic hose pressure rating is no exception. In this case, there are two primary types of pressure rating. You must know this if you want to find the most suitable option.

What is a Hydraulic Hose Pressure Rating?

A hydraulic hose pressure rating is the maximum pressure a hose can handle a specific factor. The factor can either be working pressure, burst pressure, or impulsive pressure. Why do we need this pressure rating? Following this pressure rating, you can choose the correct hose for your system. Let’s say your project’s operating pressure is 2000 PSI. The pressure rating can help you find the most suitable option for this system.

Many industries depend heavily on this factor. For example, construction, manufacturing, and agriculture need accurate pressure ratings. Hydraulic lifts, heavy machinery, and industrial machines rely on them. Otherwise, they may malfunction, leak, or lead to dangerous failures.

Therefore, you must choose the proper hydraulic hose with the correct pressure rating value. You need it for safety, efficiency, and, of course, regulatory compliance.

Different Standards for Hydraulic Hoses

Different countries use different sizing standards. Similarly, hydraulic hose manufacturing has various standards for pressure rating. These standards ensure you choose the correct size, type, and quality of the hose. However, the common standards used worldwide are SAE, ISO, and EN.

These standards ensure the system’s safety, reliability, and efficiency. Various applications from different industries depend heavily on these standards.

Understanding Hydraulic Hose Pressure Rating Chart

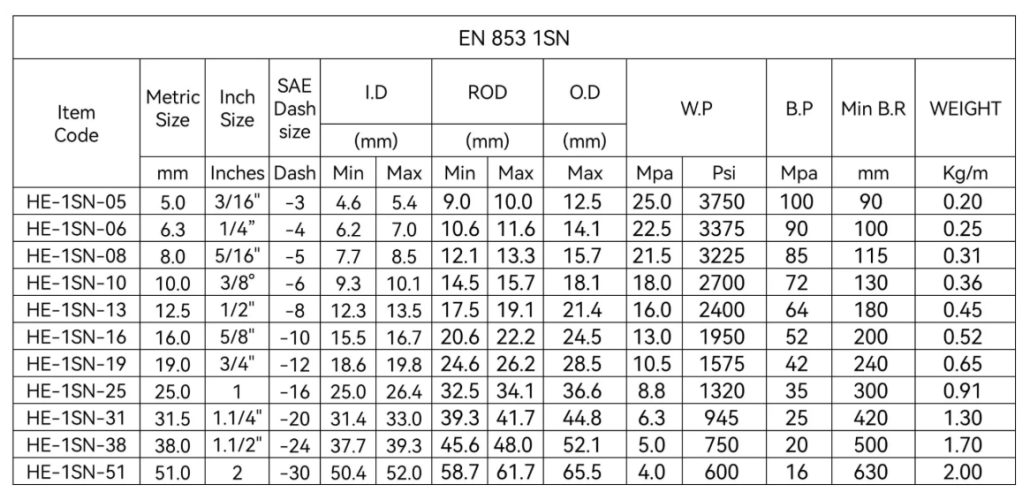

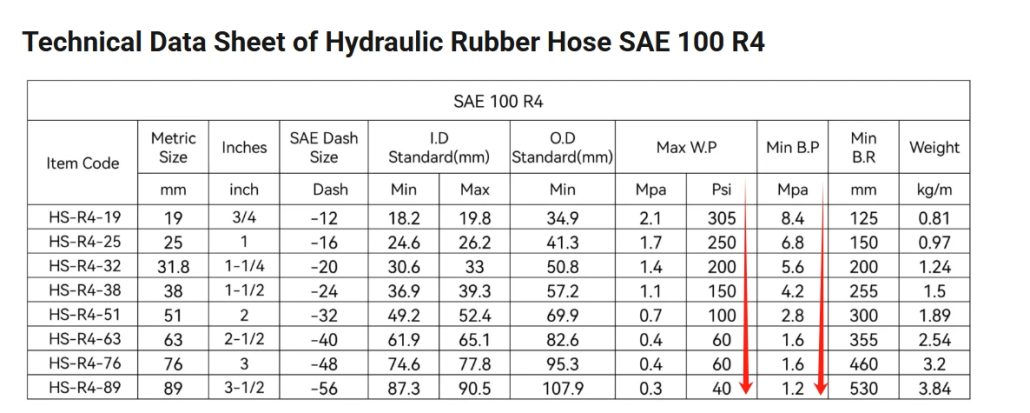

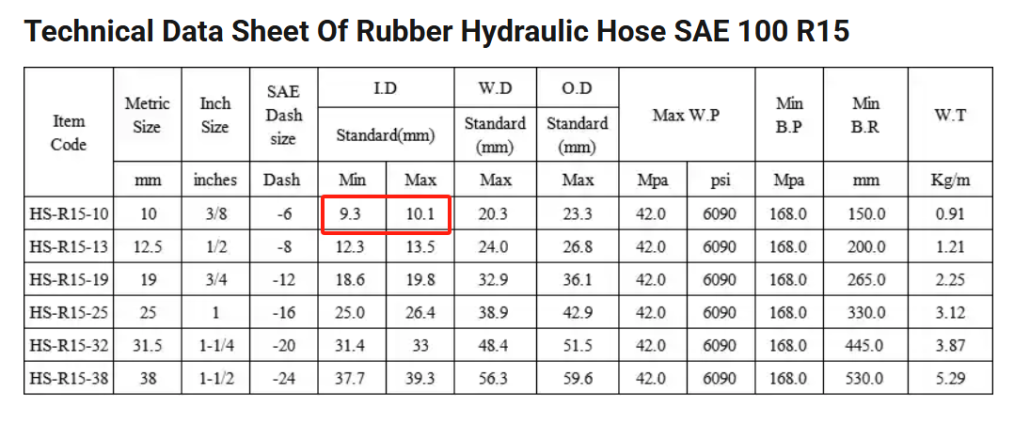

A hydraulic hose pressure rating chart usually consists of various units. It typically has metric size, inch size, dash size, ID, ROD, and OD. It also has WP, BP, Min BR, and weight. Before jumping into the table, you must understand what this abbreviation means.

(1) The item code uniquely identifies each hydraulic hose type. It can help you distinguish between different hose models with unique specs.

(2) Metric and inch size is the nominal inner diameter of the hose. It doesn’t match the exact inner diameter of the hose. Instead, it is more like an industry-standard reference.

(3) Dash size is also an inner diameter, usually measured at sixteenths of an inch. For example, -6 means 6/16″ or 3/8″.

(4) ID is the exact inner diameter of the size. The same model may have different inner and outer diameters. You can choose between these sizes based on your application needs.

(5) ROD means Reinforcement Outer Diameter. As the name implies, it is the size of the reinforced structure inside the hose. Note that the reinforcement typically provides strength and durability—the more reinforcement there is, the higher the pressure rating.

(6) OD is the exact total external width of the hose. This size includes the inner tube, reinforcement layer, and outer cover.

(7) The WP or working pressure is the maximum pressure a hose can safely handle under normal conditions. It is usually measured in MPa, PSI, or Bar.

(8) The BP or burst pressure is the maximum pressure a hose can withstand before rupturing. It is also measured in MPa, PSi, or Bar.

(9) The Min BR stands for minimum bending radius. It tells you the minimum bending radius you can achieve when installing the hose.

(10) The weight is usually the weight of a piece of hose. It is generally measured in KG per 1 meter.

#1 Hydraulic hose Pressure Rating Depends on the Hose Construction

The hydraulic hose pressure rating heavily depends on its construction. As you know, there are various types of hydraulic hoses. From braiding structures to spiral structures, there are multiple shapes and constructions.

In general, single-wire braid hoses have lower pressure ratings. On the other hand, double-wire braid hoses have higher pressure ratings. Consequently, the multi-spiral hoses have even higher pressure ratings.

#2 Hose Pressure Rating Decreases as the Inner Diameter Increases

Another factor that significantly affects the pressure rating is the inner diameter. When the inner diameter increases, the flow rate decreases, and the pressure inside the hose decreases. Thus, larger diameter hoses have lower hydraulic hose pressure ratings.

#3 The Size of the Hose May Change on Constant Pressure Rating

Even though you have the same pressure rating, the size or inner diameter may vary. As you can see, HE-1SN-05 has a constant WP of 25 MPa or 2750 PSI. However, its inner diameter may range from 4.6mm to 5.4mm, and the outer diameter may be up to 12.5mm.

Working Pressure vs. Burst Pressure: What’s the Difference?

The hydraulic hose pressure rating can be divided into two main ratings: the hydraulic hose working pressure rating and the hydraulic hose burst pressure rating. These pressure ratings are crucial to the hose’s safety and efficiency, so it is critical to understand them before choosing a hydraulic hose.

What is Hydraulic Hose Working Pressure?

As the name implies, this rating is the maximum working pressure of the hose. It is the highest level of pressure that you can continuously apply to a hose for normal operations. Hydraulic hose working pressure ensures that your hose experiences no damage or performance loss. The working pressure rating may vary based on various standards. Manufacturers typically decide which standard they will follow.

How can you determine the working pressure of the hydraulic hose? The value is usually printed on the hose. For example, it may read “** WP 160 BAR / 2320 PSI**” or “**WP 160 BAR (2320 PSI)**.”

Note that if the pressure exceeds the rated working pressure, the hose may create leaks. Although burst pressure is four times the working pressure, your hose may degrade over time and eventually fail.

Also, if the pressure is much lower than the rated working pressure, it may cause other problems. One of the main problems is inefficiencies. Your system may not get enough flow rate to function correctly. Therefore, always select a proper hydraulic hose rating to maintain safety.

What is Hydraulic Hose Burst Pressure?

The hydraulic hose burst pressure is typically three or four times higher than the working pressure. It is the maximum pressure that a hose can withstand before it ruptures. You may also call it a safety margin. You may wonder why it is necessary that much. Well, every hydraulic system may encounter sudden pressure spikes. The burst pressure typically handles those situations so your hose doesn’t fail immediately.

As said, a hose’s burst pressure is three or four times its working pressure. Therefore, if a hose has a working pressure of 2500 PSI, its burst pressure would be approximately 7500 PSI or 10,000 PSI. Note that the safety factor may change based on the type of hydraulic hose.

Some people may think they can operate at the burst pressure levels. But running a hose near its burst pressure can cause failure. Over time, the hose will degrade, eventually causing leaks. Of course, you can not expect a safety margin in such situations. So, your hose will immediately burst whenever your system experiences sudden pressure spikes.

What is a Pressure Safety Factor?

The pressure safety factor is the ratio between burst pressure and working pressure. This ratio typically helps determine the hose’s safety margin.

There are different pressure safety factors, including 2:1, 3:1, 4:1, and more. The exact ratio typically depends on the hydraulic hose you choose. For example, some jack hoses often have a 2:1 safety ratio, while water hoses have a 3:1 ratio. Most hydraulic hoses follow a 4:1 safety factor. However, specific applications or custom hoses may need a 5:1 or 6:1 safety ratio.

A 4:1 safety factor hose must have a burst pressure four times the hose’s working pressure rating. Understanding these safety factors is critical, and there are two reasons for this.

(1) You can ensure a safe and reliable system functioning. The safety factor typically prevents dangerous failures and system breakdowns. Because of this, you can reduce costly repair costs.

(2) Maintaining the safety factor is also necessary to meet compliance. Many industries have strict regulations for hydraulic hoses. They need adherence to specific pressure ratings.

Choosing the Right Hydraulic Hose

Consider a few factors when choosing a hydraulic hose. As you know, the proper hydraulic hose can help ensure a safe system and meet industry standards.

(1) The first thing you should know is the working pressure. In this case, check the hose meets your system’s operating pressure.

(2) You must choose a hose with an appropriate safety margin.

(3) The correct safety factor depends on the type of application. Therefore, when choosing a hydraulic hose, it is always necessary to evaluate the application needs. In this case, temperature, moisture, and conveying materials are critical.

Final Words

The hydraulic hose pressure rating has two central parts: working pressure and burst pressure. The working pressure is the maximum pressure that handles your system’s operating pressure. On the other hand, the burst pressure is the maximum pressure the hose can handle before it ruptures. Both of these pressure ratings are crucial for your hydraulic system.

If you have any questions, feel free to contact us.