Rigid hoses and flexible hoses have many differences. The most crucial benefit of using flexible hoses is their freedom to bend. Because of this, you can install, move, or use it in convenient positions. Well, it is impossible with rigid hoses. However, you can use various types of flexible hose material.

The right kind of flexible hose material depends on your specific project needs. This article is all about flexible hose material.

Common Flexible Hose Materials

What material is a flexible hose? The answer to this question is vast, meaning there are many options. This section will familiarize you with the flexible hose materials used in most applications. You will learn more about their pros and cons. This way, you can choose the right option for your project.

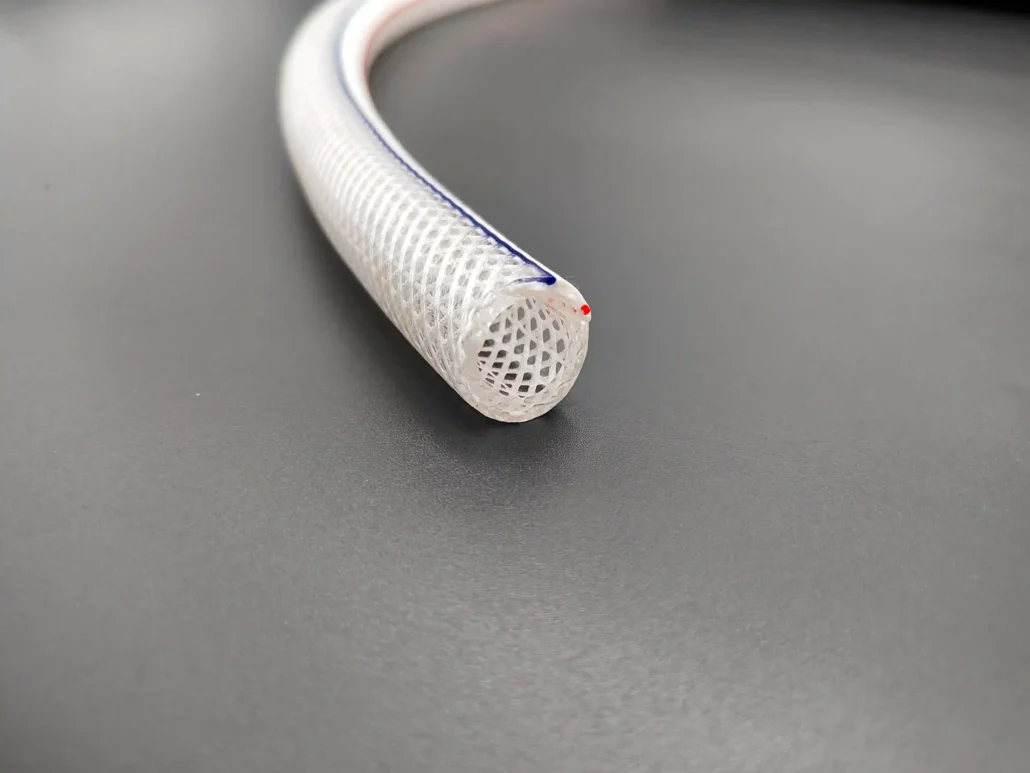

#1 PVC Flexible Hoses

As the name suggests, these flexible hoses are made of PVC or polyvinyl chloride plastic. PVC hoses are naturally flexible and lightweight. You can bend and twist them as you like, and they won’t lose shape.

PVC flexible hoses only use an extrusion process to get its shape. As you know, the extrusion process creates long and continuous profiles and tubes. First, the process heats the raw material. And then, the barrel and a screw pushes the hot molten PVC to the dies. The die gives a tube-like form that later, after cooling, forms a flexible hose.

Applications

PVC flexible hoses are prevalent in agriculture, construction, and plumbing. People mostly use them for irrigation, transferring liquids and gases. It also plays a crucial role in drainage systems. You may also find them in vacuum cleaners and air conditioning systems.

Pros

(1) PVC flexible hoses are lightweight and easy to handle and move.

(2) This flexible hose material is highly durable. They are resistant to wear, certain chemicals, and moisture.

(3) This material is flexible; you can install it around obstacles.

(4) PVC flexible hoses are cheaper than other materials, like synthetic rubbers and metals.

Cons

(1) This flexible hose material can become brittle at extreme temperatures.

(2) It is also not ideal for high-pressure applications.

(3) It also may degrade over time when exposed to UV lights.

#2 NBR or Nitrile Rubber Flexible Hose

Nitrile Rubber, or NBR, is a popular type of synthetic rubber. It comes from the polymerization of acrylonitrile and butadiene. However, NBR flexible hoses get their shapes through extrusion processes.

Applications

This flexible hose material suits automotive, industrial, and hydraulic systems. It is excellent against oils and is used primarily for carrying fuels, oils, and lubricants.

Pros

(1) Nitrile rubber is known for resisting oils and fuels. Because of this, the NBR flexible hose is perfect for carrying these substances.

(2) This flexible hose material is specifically durable in oily environments.

(3) NBR flexible hoses can handle vast temperature and pressure ranges.

Cons

(1) This flexible hose material is great against oil but offers poor weather resistance. It cannot withstand UV or ozone for a long time.

(2) Although they can endure a wide range of temperatures, they are comparatively lower than other rubbers.

(3) This flexible hose material is not ideal for use in water or moisture environments.

#3 EPDM Rubber Flexible Hose

EPDM stands for Ethylene Propylene Diene Monober. EPDM rubber is the most popular synthetic rubber. This flexible hose material is known for its excellent heat, weather, and aging resistance. Because of these properties, EPDM is a very popular material for various rubber products. The Flexible hose is one of the most common in this case.

Applications

EPDM flexible hoses are ideal for automotive, HVAC, plumbing, and agriculture use. They are perfect for water pumps, cooling, and irrigation systems. They mainly work excellently in outdoor equipment and machinery.

Pros

(1) EPDM flexible rubber hoses are durable, especially in the presence of ozone, UV rays, and extreme temperatures.

(2) This flexible rubber material is incredibly adaptable, making the EPDM flexible hose ideal for tight spaces.

(3) EPDM is great against water, mild acids, and alkalis.

(4) This flexible rubber material is cheaper than other synthetic rubber materials.

Cons

(1) Although EPDM is excellent against water and certain chemicals, it is not ideal for use against oils or fuels.

(2) EPDM rubber flexible hoses are not suitable for high-pressure applications.

#4 Polyethylene (UHMWPE) Flexible Hose

UHMWPE stands for Ultra-High-Molecular-Weight Polyethylene. This robust and durable flexible hose material is made from polyethylene with long chains of molecules. UHMWPE flexible hoses are generally produced by extrusion.

Applications

UHMWPE hoses are widely used in food processing, pharmaceuticals, chemicals, and mining. They transfer abrasive materials, chemicals, and fluids.

Pros

(1) UHMWPE is highly resistant to wear, abrasion, and impact, so it does a great job of transferring abrasive particles.

(2) This flexible hose material is highly durable in harsh environments.

(3) Polyethylene can handle a wide range of chemicals.

(4) The smooth surface of this flexible hose material produces very low friction.

Cons

(1) This flexible hose material is expensive and difficult to manufacture.

(2) UHMWPE hoses can become brittle at extremely low or high temperatures.

(3) Although this flexible hose material is great against abrasive particles, it is unsuitable for work under UV exposure. It degrades over time if you expose these hoses to UV or ozone.

#5 TPE or Thermoplastic Elastomer Flexible Hose

TPE, or thermoplastic elastomer, combines rubber and plastic materials. Because of this, the TPE flexible hose benefits from rubber and plastic. The manufacturing process involves blending elastomers with thermoplastic resins. Later, the extrusion process creates various shapes of flexible hoses.

Applications

TPE flexible hoses are helpful in many applications. They are ideal for fluid and gas transfer and are commonly used in automotive, HVAC systems, medical devices, food processing, and more.

Pros

(1) The best thing about TPE is its recyclability. Thus, it is eco-friendly, and you can recycle 100% of it.

(2) TPE flexible hose material is highly adaptable and durable. It works great against UV, wear, and abrasion.

(3) This flexible hose material is also great against various chemicals.

(4) TPE flexible hoses are lighter than traditional rubber hoses.

Cons

(1) TPE hoses may not perform well at extreme temperatures.

(2) This flexible hose material is more expensive than other types of hoses

(3) Over time, TPE hoses can lose shape if compressed too much.

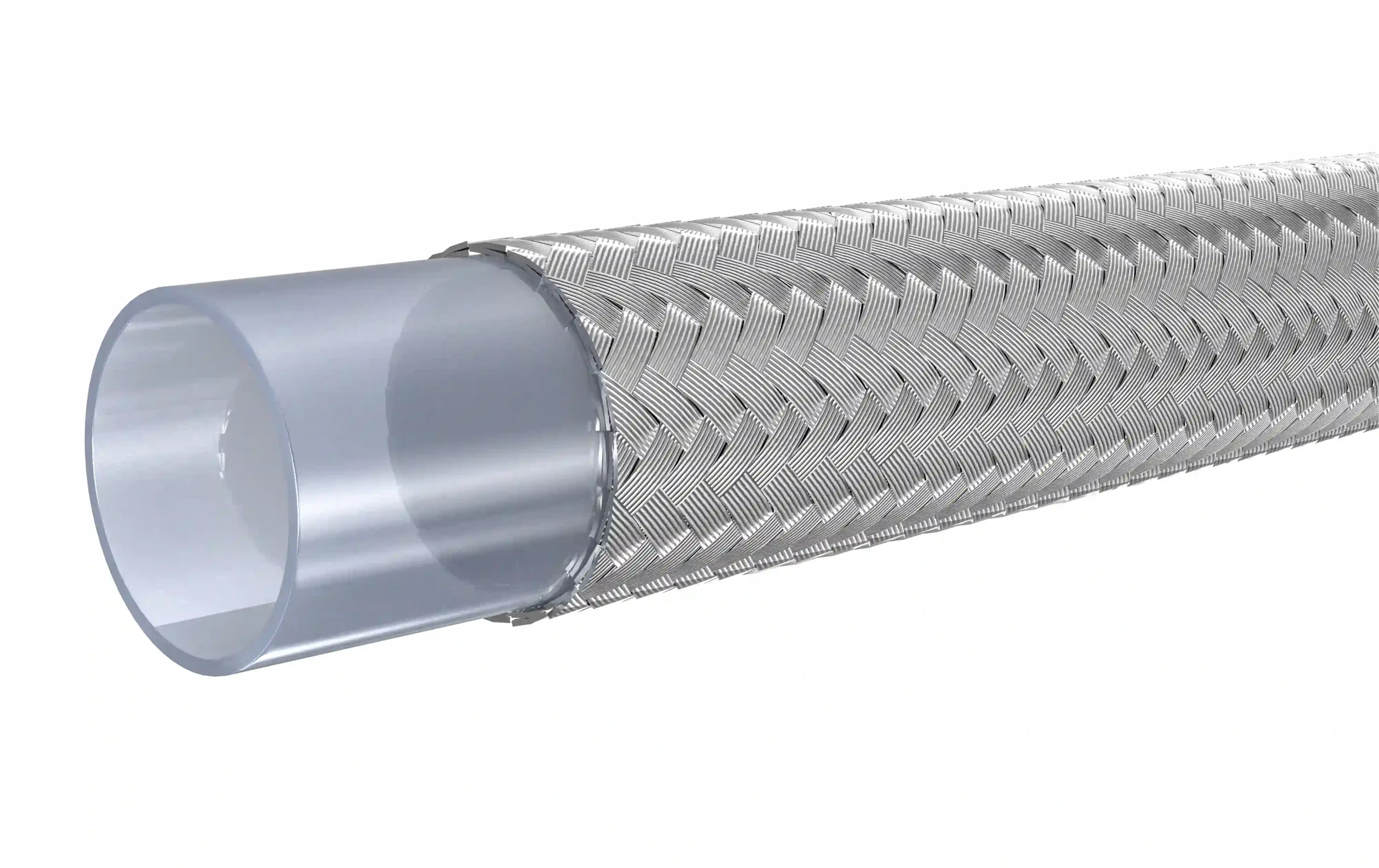

#6 PTFE Flexible Hose

PTFE stands for Polytetrafluoroethylene flexible hoses, which are made of high-performance plastic. These hoses are typically made by braiding stainless steel wire around a PTFE inner tube, which gives them extra strength and flexibility.

Applications

Since PTFE flexible hoses can resist extreme temperature and pressure, people prefer to use them in manufacturing. PTFE is specially used in chemical processing, pharmaceuticals, food and beverage, and automotive.

Pros

(1) PTFE flexible hoses can handle a wide range of chemicals.

(2) This flexible hose material can operate in extreme temperatures up to 500°F or 260°C.

(3) Being strong, PTFE is also very flexible.

(4) Since PTFE can endure extreme temperatures, it is durable in harsh environments.

Cons

(1) This flexible hose material tends to be more expensive than other flexible hose materials.

(2) There are some situations when TPFE hoses can kink.

#7 Nylon Flexible Hose

Nylon flexible hoses are known for their strength and lightweight properties. Like other flexible hoses, they are made through extrusion. Some nylon hoses are reinforced with fabrics, textiles, or metals to add strength.

Applications

Nylon flexible hoses are widely used in hydraulic and pneumatic systems. They carry fluids, gases, and powders and are great for frequent movement or tight spaces.

Pros

(1) Nylon is generally resistant to wear, abrasion, and impact.

(2) This flexible hose is ideal for use in dynamic systems.

(3) Nylon is resistant to many chemicals, oils, and solvents.

(4) The best thing about nylon is its lightweight nature.

Cons

(1) Nylon hoses are not ideal for extreme temperatures. Because of this, this flexible hose material becomes brittle in cold conditions and softens in high heat over time.

(2) Although this flexible hose material is highly durable, it may not handle as high pressure as rubber hoses.

(4) Nylon hoses also weaken under prolonged exposure to UV rays.

#8 Silicone Flexible Hose

Silicone rubber is one of the best flexible hose materials for high-temperature applications. It is made by curing silicone in a mold or through extrusion processes.

Applications

Silicone hoses are prevalent in applications where extreme temperatures are possible. They are widely used in food processing, medical, and HVAC systems. You may also need them for cooling, air ducts, and transferring liquids and gases.

Pros

(1) Silicone hoses are best known for their heat resilience. They can endure extreme hot and cold environments, making them durable in harsh conditions.

(2) This flexible hose material is non-toxic. Thus, you can use it in food and beverage applications. These hoses are also widely used in medicine factories.

(3) These flexible hoses can resist many chemicals and solvents.

Cons

(1) Silicone hoses are often more expensive than rubbers or plastics.

(2) They may lose their shape if compressed for long periods.

(3) Silicone flexible hoses are not suitable for high-pressure applications.

#9 Polyurethane Flexible Hose

PU, or Polyurethane, is another popular flexible hose material among plastics. Like other flexible hoses, PU hoses are made through various extrusion processes.

Applications

Polyurethane flexible hoses are prevalent in the automotive and manufacturing industries. They are lightweight and very durable, ideal for many dynamic environments. They may also be used in vacuum, pneumatic, and collection systems.

Pros

(1) PU flexible hose is very resistant to abrasion and wear. Thus, they must be durable for heavy-duty applications.

(2) PU flexible hoses also work well against oils, fuels, and other chemicals.

(3) Being lightweight, PU hoses offer excellent temperature resistance abilities.

Cons

(1) PU plastic is more expensive than flexible plastic hose materials.

(2) This flexible hose material can degrade with prolonged exposure to sunlight.

(3) PU flexible hose may not withstand extreme stress or high pressure over time.

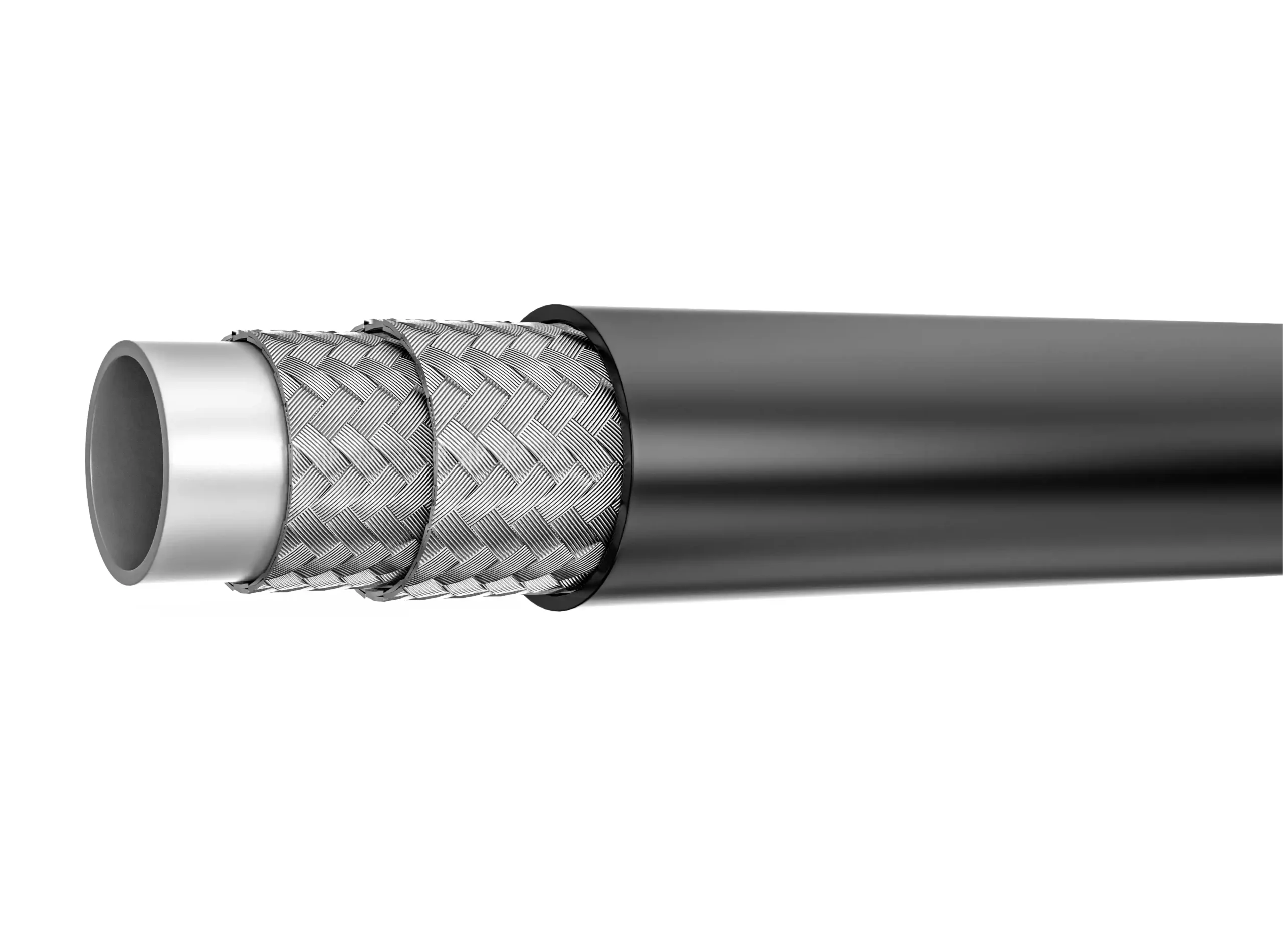

#10 Composite Flexible Hose

A composite flexible hose typically has multiple layers of materials, including stainless steel, polyester, and Teflon. The addition of various materials generally increases strength, flexibility, and durability. These hoses also have an inner core, reinforcement layers, and an outer cover. This unique structure can handle high pressure, temperature, and a variety of chemicals.

Applications

Composite flexible hoses are widely used for conveying oil, gas, chemicals, food pulps, and many more. Pharmaceuticals, food processing, aerospace, power, and refineries widely use these hoses.

Pros

(1) This flexible hose material is excellent against corrosion and wear.

(2) Composite flexible hose is lightweight and easy to handle. Although it is not lighter than plastics.

(3) This flexible hose material is versatile. This means you can transfer any fluids or gasses through it.

(4) Composite flexible hoses can handle extreme temperature ranges.

Cons

(1) Composite flexible hoses are generally more expensive than regular rubber hoses.

(2) These flexible hoses are less intense than metal ones under extreme pressure.

(3) If the outer layer is damaged, the hose can be vulnerable to wear.

#11 Stainless Steel Flexible Hose

A stainless steel flexible hose is a much more durable option. The corrugation, interlock, and braiding structure generally strengthen these flex hoses. They can endure more pressure than regular reinforcement hoses. You typically can not make these flexible hoses through the extrusion process. Instead, you must create a spiral and woven structure over an inner tube.

Applications

Stainless steel flex hoses are corrosion-resistant and durable. They are preferred in the chemical, food and beverage, automotive, construction, and oil and gas industries. They are often found in high-pressure applications, such as steam lines, fuel stems, and many industrial machines.

Pros

(1) Flex stainless steel hoses are best known for their durability. This flexible hose material is resistant to wear, corrosion, and high temperatures.

(2) Although made of metal, the corrugation, interlocking, and braiding structure make these hoses highly flexible.

(3) Flexible stainless steel hoses can withstand high pressure and a wide range of temperature ranges. Therefore, they prove to be a very reliable option for demanding applications.

Cons

(1) Stainless steel is a comparatively expensive material. It costs much more if you want SS304 or SS316 food-grade stainless steel.

(2) The manufacturing process of these hoses is also expensive.

#12 NR or Natural Rubber Flexible Hose

Natural Rubber comes from the latex of rubber trees. The latex is further processed to create usable rubber. NR flexible hoses are much cheaper and come from the extrusion or braiding processes.

Applications

NR flexible hoses are commonly prevalent in automotive and agriculture. They are ideal for general purposes such as fluid and gas transfer and may also be used in hydraulic, irrigation, and vacuum systems.

Pros

(1) NR flexible hoses are easy to install and handle.

(2) This flexible hose material offers excellent resistance to abrasion and wear.

(3) Natural rubber is environmentally friendly. It is biodegradable and more sustainable.

(4) Natural Rubber hose is a much more affordable option.

Cons

(1) NR hoses may degrade when exposed to direct sunlight.

(2) This flexible hose material has a minimal temperature range.

(3) NR hoses are susceptible to damage from ozone. Therefore, you can not use it outdoors.

#13 Special Materials and Flexible Hoses

Flexible hose manufacturing is not just limited to the above twelve elements. There are many special purposes for which you may need other materials. The following materials may not be as popular as the above ones, but they also play a crucial role in specific applications.

Aluminum Flexible Hose

Aluminum hoses are lightweight and durable. They are also used to carry air and water in various industries. Since they are lighter than stainless steel, aluminum has replaced many applications of SS flexible hoses. Aluminum flexible hoses are primarily helpful in HVAC systems. Besides, they are also prevalent in many medical and pharmaceutical applications.

Fabric Flexible Hose

Fabric hoses consist of woven fibers. These flexible hoses are polyester or nylon coated with rubber or other materials. This unique structure increases the hose’s strength and durability.

Fabric flexible hoses are lightweight and very flexible. They are ideal for applications involving frequent movement, such as the textile industry or vacuum systems.

Fiberglass Flexible hose

Although these flexible hoses may not be as popular as other materials, engineers made them only for high-temperature applications. The core of these hoses typically consists of woven fiberglass, which provides excellent heat resistance.

These hoses are essential in high heat or flame resistance applications. They can handle temperatures up to 1000°F. However, one problem is that you might not get sufficient flexibility.

Insulated Flexible Hose

As the name implies, these special hoses aim to maintain temperature control. They are energy efficient and retain heat and cold, making them ideal for refrigeration, heating, and air conditioning systems.

This insulation mainly protects the contents inside and prevents heat loss or gain. The only problem with these hoses is that they are bulkier and more expensive.

SBR Rubber Flexible Hose

SBR stands for Styrene-Butadiene Rubber. These flexible hoses are commonly prevalent in industrial applications. These are durable, flexible, and very resistant to wear and tear. They are ideal for air and water transfer.

Teflon Flexible Hose

Teflon flexible hoses are popular for their chemical resistance and high-temperature tolerances. They are more prevalent in chemical transfer applications than other rubber hoses. They are highly adaptable and ideal for the chemical, food, and pharmaceutical industries. However, they can be more expensive than other types of hoses.

How to Choose the Best Material for Flexible Hose?

You may already know that multiple materials can meet specific applications. PTFE and Teflon, for example, are excellent for chemical transfer.

On the other hand, silicone, PTFE, and composite hoses can withstand high-temperature ranges. Considering the pressure, there are stainless steel, rubber, or PVC hoses. Which one should you choose for your project? To find a conclusion, you will have to consider a few factors.

Factor #1 Chemical Compatibility

If you need to handle aggressive chemicals, you should choose Teflon or PTFE. These materials are highly resistant to a wide range of chemicals and acids.

However, if your project involves mild chemicals, you can choose various rubber hoses, like EPDM or SBR. Note that these rubbers are not suitable for all substances.

Factor #2 Temperature Resistance

If your project involves very high temperatures, you have various options. You can use PTFE, composite, Teflon, or stainless steel. However, you could choose rubbers like NBR, EPDM, or Neoprene if your project involves moderate temperatures.

Factor #3 Pressure Resistance

You can choose TPE and silicone rubber if your project involves high pressure. If flexibility is not a concern, use stainless steel flex hoses. You can also consider reinforced PTFE and rubber hoses. However, you can use PVC and all general-purpose rubbers for moderate pressures.

Factor #4 Flexibility and Ease of Handling

Not all the materials mentioned above can give you the same level of flexibility. Some can offer you more bending radius, while some can’t. If you need high flexibility, you can choose rubber hoses. However, if you need moderate flexibility, select reinforced TPE, plastics, and metal hoses.

Factor #5 Abrasion Resistance

Abrasion resistance is crucial, especially in mining and outdoor applications. In this case, you must focus on a flexible hose material that can withstand such conditions. For example, Polyethylene, TPE, Nylon, and PU are all great against abrasion. However, the UHMWPE flexible hose is the best for abrasive fluid transfer.

Factor #6 Weather and UV resistance

Many flexible hose materials are susceptible to UV light and degrade over time. If you use your hoses outdoors, consider the weather and UV resistance. EPDM, UHMWPE, TPE, or Teflon hoses are very UV resistant. You can also use stainless steel flexible hoses if you want less flexibility.

Factor #7 Cost

Finally, the cost of the project budget also affects the choice of the flexible hose material. There are some situations where more than one material can meet the demand. In such cases, choosing the cheaper product could save you a lot of investment. For example, PVC or rubber hoses are much more affordable than reinforced or corrugated materials.

Contact Us Today!

If you are looking for high-quality flexible hoses, contact Rentone Hose customer support. You can also visit our product’s description page to learn more about the various types of flexible hoses we produce daily. If you have any questions, feel free to contact our team. We have a very professional team of experts who are always ready to assist you. We welcome all types of questions from our customers.