Welding is critical work in metalworking. It has many types: laser, arc, gas, and more. A gas welding hose is one of the most popular methods here. It needs two gases: oxygen and acetylene. To supply these gases, people use oxy-acetylene hose.

This article mainly discusses the fundamentals of an oxy-acetylene gas welding hose. In specific, you will learn its properties, structure, and applications. Later, you will also learn how to choose the suitable gas welding hose for your project. So, sit tight and read the article carefully.

What is an Oxy-Acetylene Hose?

Oxy-acetylene hose stands for oxygen and acetylene hose. Thus, you can realize that this hose is combined with two separate pipes. It safely transfers gases from the cylinder to the torch.

Oxy-acetylene hoses are essential both for welding and plasma cutting. Thus, they are called oxy-acetylene torch hoses.

You may wonder why you need two hoses for this process. The technology here is that these two gases generally create high temperatures. When these gases are mixed, they make a flame that is much hotter than acetylene by itself. It is possible to reach about 3,200°C (5,800°F). You already know high temperatures are needed to weld and cut metals well.

The primary function of an oxy-acetylene hose is to transport gases (oxygen & acetylene) from the cylinder to the torch. It manages high-pressure gas safely and ensures stable flame quality. You can also benefit from its safety mechanisms. It prevents leaks and maintains hose integrity.

Properties of Oxygen and acetylene hoses

Oxy-acetylene hoses are highly flexible. This means you can bend them if necessary, and they won’t lose their functionality. They are also durable and capable of resisting wear and tear from frequent use. Thirdly, they work smoothly even in harsh environments.

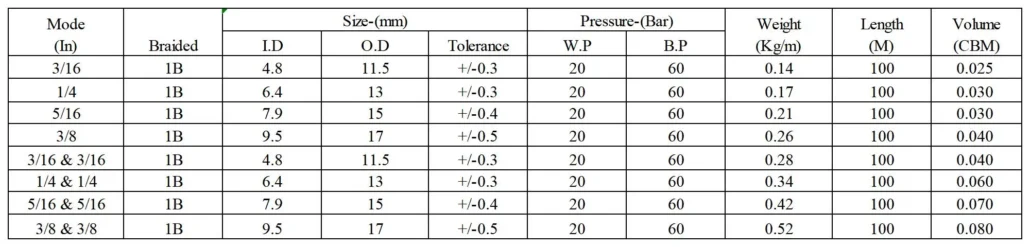

Oxy-acetylene hoses come in different sizes. They are usually Grade R hose, which is especially recommended for oxygen and acetylene. Their inner diameter ranges from 4.8 mm to 9.5 mm, and their outer diameter ranges from 11.5 mm to 17 mm. These hose sizes may have slight tolerances up to ± 0.3 mm. Finally, the recommended operating temperature is -25°C – +70°C (-13°F – +158°F).

Oxy-acetylene hoses are nonconductive, and the tube and cover are usually non-oily. This means they are safer around electrical equipment and won’t attract dust or other contaminants. Most importantly, these hoses are flame-resistant. As you know, welding and cutting involves high temperatures and flame. As a result, oxy-acetylene hoses are safe from these processes.

Oxy-acetylene hoses also offer anti-aging features. This means they resist degradation over time due to exposure to UV light, oxygen, and other environmental factors. Finally, they are also kink-resistant and don’t easily break or crack.

Structure of Oxy-acetylene Welding Hoses

An oxy-acetylene hose usually has multiple layers. Each layer plays a crucial role in the overall functionality of the hose. They ensure the hose is durable, flexible, and can withstand high pressure. You will see a cross-section of four layers if you cut an oxy-acetylene hose vertically.

Inner Tube

The first layer you see from the inner core is the inner tube. It is the main tube that carries oxygen or acetylene. This layer is mainly made of SBR rubber. SBR stands for Styrene Butadiene Rubber.

As you know, SBR works great in contact with water, gas, and certain chemicals. Thus, the inner tube of an oxy-acetylene hose ensures a safe conduit of oxygen and acetylene.

Reinforcement Layer

The reinforcement layer is right above the inner tube. It surrounds the inner tube and gives it strength against pressure. This layer is typically made of high-tensile helical polyester cords. Some oxy-acetylene hoses may have steel wire braided. However, this depends mainly on the hose’s flexibility and strength.

Outer Cover

The outer cover of the hose mainly protects the inner two layers from external damage. It is made of SBR and EPDM compound rubber. As you know, SBR and EPDM rubber are suitable for their excellent abrasion resistance. These two rubber materials are also prevalent for weather and ozone resistance. Consequently, in oxy-acetylene hoses, these materials ensure safety and durability.

Surface

The final layer is the surface layer. It is usually wrapped with different protection guards. This surface improves the grip and handling. Some hoses may feature a ribbed surface for added durability and ease of use.

Application of oxy-acetylene hose

Oxy-acetylene hoses are necessary in various applications. However, they are often used mainly in welding and cutting processes.

Oxy-acetylene welding hoses play a crucial role in the welding process. These hoses combine oxygen and acetylene to produce intense heat, usually rising above the metal’s melting point. This process can help you a lot when joining two metal parts. Because of this, people often call this type of welding gas welding.

Only inert gases are used in laser welding, while argon gas is used in arc welding. Therefore, welding hoses vary depending on the type of welding.

On the other hand, when cutting, you can use the same idea to get through a metal plate. When these gases come together, they create intense heat that melts the metal plate. The process is known as the gas-cutting process.

Oxy-acetylene hoses also play a crucial role in the heating, bending, and flame-cleaning processes. In these uses, the heat is controlled and set at a lower temperature than the melting point. Thus, the metal becomes soft, easy to bend, and clean.

How to Choose the Right Oxy-Acetylene Hose or Gas Welding Hose for Your Project

Like other products, you must consider a few factors to choose the correct gas welding hose. By considering them, you can ensure the best outcome of your project. In addition, you can get the best price for your whole operation.

Factor #1 Application

The first and most crucial factor to evaluate is your project. What type of hose does it need? Does it involve welding, cutting, heating, bending, or cleaning? What is the working temperature? Does it involve high pressure?

As you know, different welding and cutting processes usually require hoses of varying qualities. For example, the heat produced in welding and cutting is generally more intense than in heating applications.

Factor #2 Material Compatibility

Material is also critical in welding, cutting, and heating. Oxy-acetylene hoses or gas welding hoses are specially designed for oxygen and acetylene. But if your gas welding needs propane or natural gas, you may have to look for other hoses. Note that inappropriate material may gradually degrade due to the reaction by the gas.

Factor #3 Product’s Specs

Next, look for the correct specifications. In this case, you can consider the inner diameter or outer diameter. A, B, and C are the most popular welding hose sizes. Oxy hoses and acetylene hoses are usually of all three types. You may need to find the correct adapter for different sizes. Usually, you can find A to B, B to B, or B to A.

Factor #4 Safety & Durability

Safety features and durability are always paramount. Look for hoses with robust reinforcement layers and durable outer covers. Typically, all Rentone Gas Welding Hoses come with a wrapped outer cover. Because of this, these gas welding hoses ensure a long-lasting lifespan.

Factor #5 Cost & Efficiency

Finally, consider cost and efficiency. Efficiency depends on price, lifespan, upkeep, and performance. You must balance the cost with the hose’s efficiency. After considering the above five factors, you can choose the best gas welding hose for your project.

Frequently Asked Questions

Which kind of hose is used for acetylene gas?

As the name suggests, this hose is generally suitable for carrying acetylene gas. This hose is typically red and designed to handle acetylene. There are some pressure requirements as well. The working pressure (WP) is usually 20 bars, and the burst pressure (BP) is 60. This kind of hose is usually Grade R.

What is the difference between acetylene and oxy-acetylene?

Acetylene is a flammable gas commonly used as a fuel in welding and cutting. It burns at a high temperature, making acetylene hose suitable for these applications. On the other hand, oxy-acetylene is a combination of two separate hoses. One is blue or green, and the other is red.

When mixed, these gases produce a much hotter flame than acetylene alone. You can achieve a temperature of around 3,200°C (5,800°F). As you know, this high temperature is necessary for efficiently welding and cutting metals.

What is the maximum pressure for an acetylene hose?

When choosing an oxy-acetylene hose, you must check its speciation. This table usually has ten columns for each hose model. To check the pressure rating, find WP and BP. WP stands for working pressure, and BP stands for burst pressure. The WP is usually 20 bars for oxy-acetylene hose, and the BP is generally 60 bars, which in PSI is 290 psi and 870 psi.

What is the color of the acetylene hose?

The acetylene hose is usually red, an international standard for all acetylene hoses. This distinct color coding helps you identify it from the oxygen hose. The oxy-acetylene hose usually comes with two different hoses: one oxygen hose, which is blue or green, and the red acetylene hose.

Contact Us Today

If you have any questions, feel free to contact us. Rentone Hose manufactures all types of hoses. You can get industrial hoses, hydraulic hoses, hose fittings, and various protectors. Our team of experts is always happy to answer your queries.