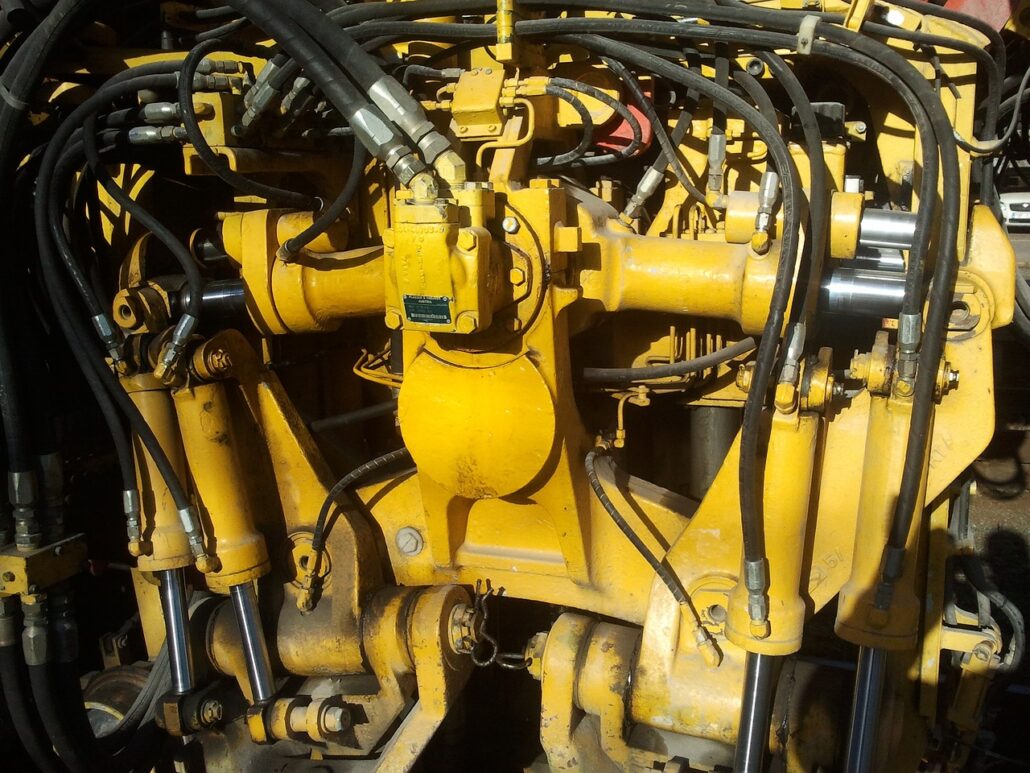

We are all more or less familiar with hydraulic systems and how they work. They are often found in excavators, forklifts, automobiles, and aircraft. A hydraulic hose connection usually links different parts of a machine together.

There are several ways to connect the hose to the other parts. The most common are threaded, crimp, quick connect, flange, and barbed. This article discusses all of these ways. It also lets you choose the right fittings for your project. If you are a business owner or a supplier, this article can help you understand the different types of fittings people often need.

Types of Hydraulic Hose Connection Methods

You can connect hydraulic hoses in many ways, such as thread, crimp, flange, and quick connect. Each method requires different types of hydraulic hose fittings. However, their main goal is to ensure leak-free and reliable joints. As a result, you can safely work with your system. This diversity generally appears for some reason.

#1 Hydraulic systems are used in a wide range of applications. Every situation may require a unique hydraulic hose connection method.

#2 Each hydraulic system may have different pressure levels. Based on this, the types of hydraulic pipe fittings also differ.

#3 Another reason is how easily you can connect hydraulic hoses. Ease of upkeep and repairs also matter in this case.

Method #1 Threaded Connection

As the name suggests, this hydraulic hose connection method uses screw threading. It is a very convenient system for most hydraulic connections. Besides, it is also a widely used method. The threads can be both external and internal. In the case of male threads, it is external, while for females, it is internal.

Whatever the type of thread, the main goal of a threaded connection is to make a leak-proof seal. This connection method also has other benefits.

- When properly installed, a threaded connection provides a tight and leak-free seal.

- These connections can handle high pressure. Because of this, they are suitable for high-pressure jobs.

- Threaded hydraulic pipe connections are versatile. They are used in a wide range of applications.

- They are durable and easy to install.

How to Connect Hydraulic Hose with Threaded Pipe Fittings

Connecting hydraulic hoses with threaded fittings is relatively easy. Anyone with basic mechanical skills can do it.

First, you must select the correct type of hydraulic hose fittings. You can find the exact size & kind based on the specs of the hose and components.

Next, you can wrap thread sealant around the external threads. In this case, you can also use Teflon tape. Wrapping is necessary to seal the tiny spaces on the threads. Therefore, it ensures a leak-free hydraulic connection.

Next, slide the fittings into the hose. If the tightening is difficult, use a regular or pipe wrench. Ensure that you don’t harm the hose or pipe.

Finally, test the system and check for any leaks.

Different Types of Threaded Hydraulic Pipe Fittings

There are five different threaded hose fittings in five different shapes. They are:

Ferrules

Ferrules are like long metal rings. They are the simplest yet most used fittings. Ferrules are typically used to join two hoses or one hose & one fitting. They are usually ideal for high-pressure applications. The most common models are 00110, 00210, 00400, 00621, 01400 and 03310.

Flat Surface Male & Female Thread Fittings

These fittings usually have flat mating surfaces. It means they meet at the flat and plain surface when you tighten a male and female part. That’s why they called flat surface thread fittings.

This structure creates a tight seal between two fittings. It is commonly used in reusable connection jobs. This hydraulic hose connection is highly reliable and super easy to install.

Compression Fittings

Compression fittings use a nut and a ring to compress the hose onto the fitting. In this case, the ring is called ferrule. This mechanism also creates a tight seal. These hydraulic pipe fittings are suitable for various pressures. Besides, these fittings are ideal for frequent assembly and disassembly jobs. You can also use it for both low and high-pressure hydraulic systems.

Swivel Fittings

These hydraulic pipe fittings are designed to allow the hose to rotate. Their unique feature prevents twisting and kinking. You can use these fittings for applications where frequent movement is common.

Adapter Hydraulic Hose Fittings

These types of hose fittings connect hoses with different thread types or sizes. They help connect various components and systems.

Adapter Hydraulic Hose Fittings connect hoses to components with mismatched threads or sizes. They are ideal for a wide range of hydraulic systems.

Method #2 Flange Connection

These hydraulic connections are also employed in a wide range of systems. Flange connections are sturdy, ensuring leak-proof sealing. Because of this, they work best in systems with a lot of pressure. You may often find it in heavy machinery.

You know, thread connections are prone to loosening under vibrations. For flange type, you don’t have to worry about that.

Flange connections have three main types. #1 Split flange comprises two halves that clamp around the hose and are bolted together. #2 A Flat face flange features a smooth and flat sealing surface. #3 Raised face flange has a raised surface around the bore. All these types are ideal for medium—to high-pressure applications.

To install flange connections, align the flange faces and secure them with the bolt. One trick is to apply even torque to tighten the flanges in place securely. This practice generally ensures no leaks.

Method #3 Quick Connect Hydraulic Hose Fittings

Hydraulic Quick-connect Fittings are ideal for frequent opening and closing jobs. They are easy to use, and you can quickly set them up. Quick-connect hydraulic hose fittings are commonly used in many industries.

There are various types of hydraulic quick-connect fittings. #1 Push-to-connect fittings are user-friendly. They need a simple push to secure the connection. These fittings are ideal for low-pressure jobs. #2 Ball-lock fittings are more robust. They use a locking mechanism for tight seals. This type of fitting is suitable for high-pressure jobs.

To connect these hose fittings, align the male and female ends. Then, you can push them together until you hear a click or feel them lock. When disconnecting, pull back the release collar.

Method #4 Crimp Connections

For permanent joints, crimp hydraulic connections are famous. It creates strong and leak-free seals. Therefore, you may often find its use in high-pressure jobs. As you know, the above four types can be opened or closed anytime. However, opening it is typically not recommended once you have created crimp connections.

The crimping process has several steps. #1 Measure and cut the hose according to your needs. #2 Then, clean the hose and fittings. Note that contaminants may create leaks in the future, so cleaning is crucial. #3 Mark the insertion depth for the perfect connection. #4 Determine the appropriate crimp diameter for the process. #4 Now, crimp the connection using a crimping tool. #5 Test the hydraulic hose connection.

Method #5 Barbed Connections

Barbed connections are another trendy method in hydraulic systems. As the name implies, these fittings are designed with barbs that grip the inside of the hose. You can compare this type with quick-connect hydraulic hose fittings. However, barbed connections are easier than quick-connect fittings.

Barbed fittings can be used for low to medium pressure. They aren’t suitable for high-pressure scenarios, though. Again, it’s not ideal for frequent disconnections, either. Pick quick connect parts for jobs that need to be done quickly.

The Importance of Accurate Hydraulic Connections

As you know, hydraulic flow always generates high pressure, which is used in many jobs. One leak can negatively impact the work and even raise safety issues. So, it’s always essential to have correct hydraulic connections. We can observe the importance of the proper hydraulic hose connection in some key areas.

Consistent Hydraulic Flow

First, the accurate hydraulic connection gives you a guaranteed job. It ensures a consistent flow in the whole system. That is how you can prevent pressure drops. The proper hydraulic pipe connection ensures that actuators work at their highest capacity.

Erratic movement is another issue when the flow isn’t steady. It usually happens because the fluid flow is lower, and the response time is slower. To avoid these problems, you must ensure the fluid flow stays steady.

Overall System Performance

Your system’s quality depends on how well the hydraulic connection works. Bad joints can cause issues and usually slow down the system. A good joint can help you be more productive and, in the end, make your system run better.

Safety

An excellent hydraulic hose connection also ensures safety. As you know, hydraulic systems often work under pressure. If your system leaks, you may have to worry about safety. These leaks or failures can create safety issues. Reliable hydraulic hose fittings reduce this risk.

Lowering the Cost of Repairs

Again, due to poor connections, leaks and failures may appear. These situations can sometimes damage the system components. In the end, poor hydraulic connections increase the repair costs. None of these will happen if you ensure good joints at the beginning. So, always make sure you have correctly linked hydraulic hoses.

Durability of the System

An excellent hydraulic hose connection reduces wear and tear on system parts. It can also withstand the rigors of daily work, which typically prolongs the lifespan of your system.

Conclusion

So far, we have discussed various hydraulic hose connection methods. You now know about five prevalent ways to connect a hydraulic hose. Each method has its own uses and benefits.

As you know, hydraulic systems use fluid to transmit power. In this case, hydraulic hose connections ensure leak-proof operations. In addition to fittings and connections, the quality of rubber hoses also matters.

Contact us if you need rubber tubes, fittings, or couplings. We offer various hydraulic and pneumatic hoses, fittings, couplings, and after-sale services. So, whenever you need an answer, contact us.