Product Description

Hydraulic couplings are special tools to connect and disconnect hydraulic systems’ machinery, equipment, or hoses. It quickly and safely transmits hydraulic fluid between different components without needing tools. Hydraulic couplers are essential in hydraulic systems for easy assembly, disassembly, and maintenance.

Materials of Hydraulic Coupler

Hydraulic couplings are made from durable materials. These include steel, stainless steel, brass, and other alloys. These materials can withstand high pressures, temperatures, and impact in hydraulic systems.

Features And Benefits of Hydraulic Couplings

- Excellent resistance to corrosion

- Highly versatile for several applications

- Prevent leaks and ensure efficient transfer of fluid

- Easy assembly, disassembly, and maintenance

- Highly durable to provide a long service life

Hydraulic Coupler Types

- Hydraulic Quick Couplers: They are used for quick connections and disconnections without needing tools. The couplings are frequently used in applications where speed and ease of use are necessary.

- Threaded Couplings: Certain hydraulic couplings use threaded couplings for a tight and leak-resistant connection. They are frequently used when a durable and long-lasting connection is required.

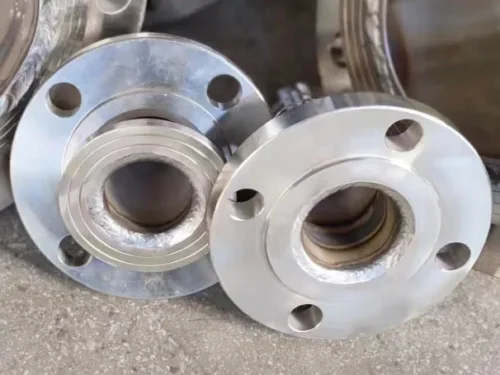

- Flange Couplings: Two flanges are bolted together to provide a robust and reliable connection. They are frequently used in high-pressure hydraulic systems.

- Flat–Face Couplings: Flat-face couplings are designed for applications to minimize the spill-out of fluids where connection and disconnection are required. The risk of fluid leakage is decreased by their flat mating surfaces, creating a tight seal before the valves open.

Applications of Hydraulic Couplers

- Agricultural equipment

- Construction machinery

- Automotive hydraulic systems

- Industrial machinery