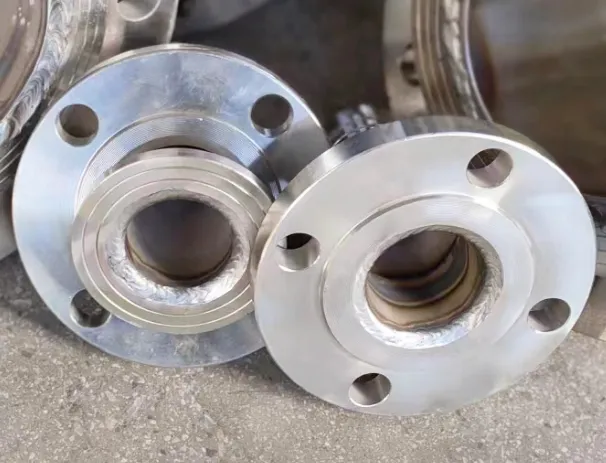

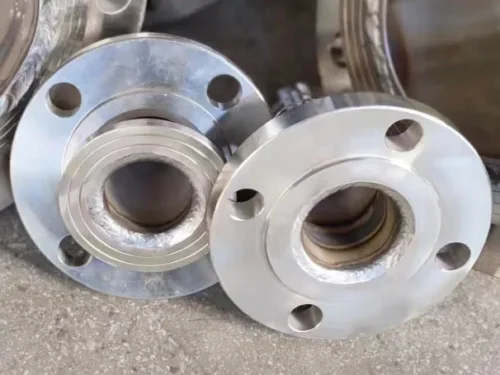

Product Description

The flange joint is designed to join hoses, valves, fittings, and other device to form a piping system. Flanged joints are typically screwed or welded. Flange joints are made to provide a seal by bolting two flanges together with a gasket between them. It is essential in various industries, such as chemical processing, water treatment, food and beverage, and manufacturing.

Materials of Rentone's Flange Joint

Flange jointjoints are usually made from a variety of materials. These include carbon steel, stainless steel, alloy steel, and cast iron. The choice of material depends on the nature of the material being transported, temperature, and pressure conditions.

Features And Benefits of Flanged Joints

- Easy to install and maintain

- Excellent flexibility and durability

- Provide a secure and leak-tight seal

- Prevent the leakage of fluids or gases and minimize the risk of contamination

- Offer a cost-effective hose solution

Types of Flange Joint

-

Weld Neck Flange: This flanged joint has a neck welded to the pipe. It offers superior strength and structural support.

-

Slip-On Flange: This type of flange is welded in place after it is slid over the pipe. It is less solid than a weld neck flange but is more straightforward to align.

-

Socket Weld Flange: Similar to slip-on flanges, a socket-welded flange requires the pipe to be placed into it before welding.

-

Threaded Flange: The flanged joint has internal threads, and the pipe has external threads. These are used where welding is not feasible or for low-pressure applications.

-

Blind Flange: This flange is made of a solid disk without a center hole. It seals the end of a pipe or a pressure vessel. It is commonly used for maintenance or to block off a section of a piping system.

Flanged Joints Standards

Flange joint designs are governed by the international standards ASME B16.5 & B16.47 in line with the American Society of Mechanical Engineers (ASME).

International Production Standard: GB/T9112-2010 (GB9113·1-2010~GB9123·4-2010)

Chemical Department Standard: HG5010-52~HG5028-58、HGJ44-91~HGJ65-91、HG20592-2009 and HG20615-2009 series

Machinery Department Standard: JB81-59~JB86-59、JB/T79-94~JB/T86-94、JB/T74-1994

Pressure Vessel Standard: JB1157-82~JB1160-82、NB/T47020-2012~NB/T47027-2012、B16.47A/B B16.39 B16