Product Description

Camlock fitting is also referred to as camlock coupling. It is a type of hose coupling that connects two hoses or pipes without any tools. They are commonly used in various industries to transfer fluids, powders, or pellets. This is especially true in low-pressure fluid handling applications. Camlock couplings contain a male and female end and arms to help lock the ends together when connected. The purpose of the safety pins is to keep the cam arms from unintentional disconnection while in use. Camlock couplings are primarily made of stainless steel, brass, or aluminum.

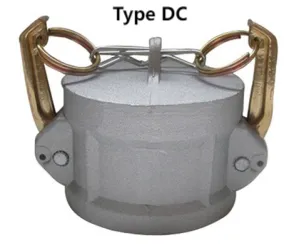

Type of Camlock: A, B, C, D, DC, DP, E, F

Size: From 1/2” to 10”

Body Material: Stainless Steel, Aluminum, Brass

Cam Arm Material: Stainless Steel or Brass

Gaskets Material: NBR, EPDM, Viton, PTFE

Type of Thread: NPT, BSP, PT

Features And Benefits of Camlock Coupler

- Easy to use and handle

- Highly versatile to use for liquid, powder, and gas transport

- Highly durable and abrasion-resistant

- Cost-effective

How Does A Camlock Work?

A male adapter and a female coupler of the coupling are required to make a connection.

Step 1: Insert the male adapter of the same size into the female coupler

Step 2: Close both arms and handles at the same time

Step 3: Disconnect the handles and take out the male adapter

Applications of Camlock Fittings

The camlock fittings are highly versatile and cost-effective in almost any industry where liquids or powders are frequently used. Common uses include manufacturing, agriculture, fuel and oil, gas, pharmaceutical, chemical, food and beverage, military applications, etc.

Types of Camlock Fittings

Type A: Male Cam with Female Thread

Type B: Male Cam with Female Thread

Type C: Female Cam with Hose Tail

Type D: Female Cam with Hose Tail

Type E: Male Cam with Hose Tail

Type F: Male Cam with Male Thread

TYPE DC: Dust Cap for Male Cam

TYPE DP: Dust Plug for Female Cam