“Hydraulics, the life force of modern machinery.” Hydraulic systems are everywhere. A hydraulic system is a preferred choice for small tools and large machinery. Unlike an electric or mechanical system, a hydraulic system can give you a large lifting force from a compact size. Hydraulic high-pressure hoses are a crucial part of these systems.

Hydraulic high-pressure hoses are also called power hoses. They usually come in a variety of sizes and materials. When considering size standards, you have options like ISO, SAE, and EN. In addition, when you consider materials, you have three options: rubber, plastic, and PTFE. We are not done yet. When you consider the type of rubbers, you still have many choices. So, choosing the right kind is crucial. We hope you will learn how to choose the right hydraulic high-pressure hose for your job by reading this article.

What is a Hydraulic System

A hydraulic system uses fluid to transfer energy and perform various jobs. When the pump moves the fluid, it creates pressure in the system. This pressure is transmitted through the hoses and pipes to the hydraulic motor or cylinder.

The motor converts this hydraulic energy into rotational motion. In manufacturing plants, people often use this strategy in many machine tools. On the other hand, the cylinder converts the hydraulic power into linear motion. You may frequently find this strategy in machinery and heavy-duty vehicles.

During this process, control valves regulate the flow and direction of the fluid. In this way, you can control the system precisely.

Overview of Hydraulic System Components

A hydraulic drive system has several components. When you combine all these components, people call it “hydraulic supply.” Within the system, each part is necessary.

The first and most important part is the hydraulic pumps. People call them the heart of hydraulic systems. Their main job is to create hydraulic power. To do this, the pump pushes the power fluid from one component to another. In this way, the pump converts the mechanical energy into hydraulic power.

In real-world applications, you can find various types of hydraulic pumps. Some names for these pumps are gear, piston, and rotor.

Next are hydraulic hoses. Their primary function is to transport the power fluid and connect other components. They have to bend and hold up under a lot of stress. They’re known as “power hoses.” They’re made of various materials. Rubber, plastic, and PTFE are among the most popular goods. We will discuss these in the following sections.

Hydraulic oil, hydraulic accumulators, valves, and switches are other essential parts.

Hydraulic motors generate rotational motion using hydraulic power. It is prevalent in many manufacturing factories. However, small tools, like automated fasteners, are often powered by pneumatics.

Hydraulic cylinder components generate linear motion by applying hydraulic power. This strategy is prevalent in machinery or heavy-duty car’ control systems.

Why is the Hydraulic System Preferred?

Hydraulic systems are preferred for several reasons. First, they provide high power in a compact size. Second, they offer accurate control and quick response. Third, hydraulic systems are reliable and durable. Fourth, compared to pneumatic systems, they produce more force. Fifth, they are safer in explosive environments.

For example, hydraulic systems are used in excavators and cranes, as well as in the manufacture of presses and lifts. In agriculture, tractors and harvesters use hydraulic systems. Moreover, hydraulic systems are present in every aircraft control system and automotive brake.

What are Hydraulic High-Pressure Hoses?

As the name suggests, these pipes or tubes are for high-pressure jobs. People also call it a power hose or pressure line.

Hydraulic high-pressure hoses can handle pressure easily. Their main job is to transfer fluid power from one component to another. The reinforcement ensures an efficient conduit in a hydraulic system.

A typical hydraulic high-pressure hose has multiple reinforcement layers. The higher the pressure, the more sturdy the structure will be. Metal wires, synthetic rubber, or thermoplastics are standard.

There are many types of hydraulic high-pressure hoses. In the following few sections, we will highlight all possible kinds. There are various categories based on different criteria.

Different Types of Hydraulic High-Pressure Hoses

You may need power hoses in different situations. It may be an extremely hot or cold environment. Or it may be in a chemical environment. Moreover, you may need it under extremely high pressure. Or, you may need it in a very compact space. So, you see, there are many different situations. This is the only reason behind the diversity of hydraulic high-pressure hoses.

Depending on the material, there are three main types of hydraulic high-pressure hoses. However, hydraulic rubber hoses are most common here.

Type #1 Hydraulic Rubber Hoses with Reinforcement Metal Wires

Hydraulic rubber hoses are a very famous power hose in many situations. They usually come with reinforcement metal wires. The main construction is made of synthetic rubber. The type of rubber varies depending on different needs. In general, you can find three main types of synthetic rubber used.

Nitrile Hydraulic Rubber Hose

These hoses are suitable for hydraulic systems where oil resistance is essential. These rubber hoses come with a reinforcement of high-tensile steel wire. This construction improves the strength of the power hose.

Nitrile hydraulic rubber hose is highly abrasion-resistant. You can use it in temperatures from -35°C to +120°C (-30°F to +250°F). It is flexible and, of course, durable.

Neoprene Hydraulic Rubber Hose

This hydraulic rubber hose is also a famous power hose used in many hydraulic systems. People prefer this power hose for its versatility and balanced properties. Similar to nitrile, it also has reinforcement with metal wires.

The good side of neoprene hydraulic rubber hose is its excellent weather resistance. It works great in moderate oil and chemicals. Neoprene has a good chemical resistance. You can use this hydraulic rubber hose in temperatures ranging from -40° F to +275° F (-40° C to +135° C).

EPDM Hydraulic Rubber Hose

The short for Ethylene Propylene Diene Monomer is EPDM. It is a very famous material used in many outdoor applications. For hydraulic rubber hose manufacturing, the use of EPDM is also typical.

EPDM’s best feature is its high-temperature resistance. You can use it in applications with temperatures between -50°C and +120°/150°C (-60°F to +250°/300°F). EPDM hydraulic rubber hoses are also flexible and have superior ozone resistance.

Limitations of Hydraulic Rubber Hoses

- Hydraulic rubber hoses reinforced with steel wire are relatively heavy.

- Although nitrile and neoprene are suitable for chemical resistance, EPDM is not good at it.

- Although EPDM rubber is suitable for outdoor use, other rubber may not work well outdoors.

Type #2 Thermoplastic with Reinforcement Textile Materials

Thermoplastic is a type of plastic. When heated, it becomes soft and hardens when cooled. You can shape anything you like; it won’t lose its properties. Similarly, you can make hydraulic hoses using thermoplastic with reinforcement textile materials.

Thermoplastic hydraulic hoses are prevalent in many applications. Hydraulic tools, mobile equipment, and industrial automation systems are noteworthy.

Benefits

- Thermoplastic is incredibly lightweight compared to other hydraulic hoses.

- These rubber hoses can work against a wide range of chemicals.

- They are flexible and non-conductive

Limitations

- Thermoplastic hydraulic hoses may not be suitable for high-pressure jobs.

- They are also temperature-sensitive.

- These hydraulic hoses can cost more.

Type #3 Teflon with metal inserts or PTFE Hydraulic Hoses

PTFE or Teflon hydraulic lines often have metal parts inside them. These special materials are made to work in harsh situations. They are used in food and drinks, chemical plants, airplanes, and medicines.

Benefits

- PTFE hydraulic hoses have an excellent chemical resistance ability.

- They can also work in extreme temperatures. It typically ranges from -400 to 500°F (-240 to 260°C).

- PTFE hydraulic hoses offer a low friction coefficient.

- They are non-reactive and flexible.

Limitations

- PTFE or Teflon hydraulic hoses are more expensive.

- They are heavy and have limitations in pressure ranges.

- They are not as flexible as rubber high-pressure hoses.

Six Criteria for Correct Hydraulic High-Pressure Hoses Selection

As you have already seen, hydraulic hoses can be of various types.

You have three options based on materials: hydraulic rubber hoses, thermoplastic, and PTFE. Again, based on reinforcement type, you have two options: spiral and braided.

Once again, there are three options for rubber types: nitrile, EPDM, and neoprene. So, it is evident that you must be careful during the selection process.

Hydraulic Hose Size

Determine the size of the hydraulic hose your project usually needs. Since all equipment follows standards, you can also check the standard sizes. Regarding hoses, you can check for diameters (ID, WD, and OD), length, and weight.

Hydraulic System Pressure

Assess the hydraulic system pressure. Check the required working and max pressure of your project. Always consider the safety factor (4: 1). This ratio (4: 1) states that your project working pressure must be a quarter of the hose’s burst pressure.

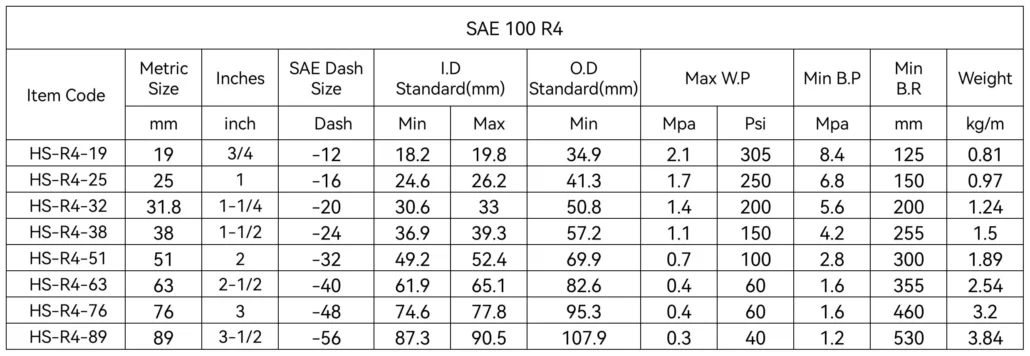

It’s good that Rentone Hoses are already made following this ratio. For example, Rentone Hose SAE 100 R4 has a minimum BP of 8.4MPa and a WP of 2.1 MPa. See the Difference? The BP is four times the WP.

Hydraulic System Impulse Pressure

Check the impulse pressure of your hydraulic system. The safety factor is 4:1. Some applications may produce impulse pressure during operation.

Considering the impulse pressure and the safety factor, you may need bigger hoses. As you know, the bigger the hose, the less pressure there is. So, it might not be suitable for your applications. To solve this issue, hydraulic systems are equipped with overflow valves.

Temperature & Chemical Compatibility

Check your system’s highest temperature. Choose a hydraulic hose with a higher range.

Then, check whether your project handles chemicals. In this case, the types of rubber material matter a lot. Neoprene and nitrile are suitable for chemical resistance.

Bend Radius

Bend radius also matters when you choose a hydraulic hose for your job. In this case, hydraulic rubber hoses are more flexible. They can create more bend radius than other materials, like thermoplastic or PTFE.

Common Questions (FAQ)

What is the ISO standard for hydraulic hoses?

The ISO standard for hydraulic hoses is 18752:2022. It defines the standard specifications for rubber pipes and the assembly requirements. Every manufacturer must adhere to a standard. Rentone Hose does the same and adheres to SAE and EN requirements. In this factory, you can also make rubber hoses using ISO standards.

What are the grades of hydraulic hoses?

ISO 18572 has four well-known grades, Grades A to D. If you consider the SAE standard, you have options like SAE100R. Well, SAE 100R has grades from R1 to R17. If you look for EN standards, you still have many options: 1SC, 2SC, 4SP, and 4SH. FYI: Each grade comes with varying pressure ratings and sizes.

What psi is a high-pressure hose?

PSI stands for “pounds per square inch.” In places like the UK and the USA, it’s an imperial measuring system.

The value of high-pressure pipes is based on their grades and standards. For instance, SAE 100 R1 hydraulic tubes can handle up to 100MPa, which is 14500 PSI. On the other hand, SAE 100 R17 hydraulic lines can only handle up to 21MPa (3045PSI). Also, the highest pressure in EN HS 1C 06 to 25 is between 8.8MPa and 22.5MPa, 1280PSI and 3260PSI.

What material is used in high-pressure rubber hoses?

Hydraulic high-pressure rubber hoses are made of synthetic rubber. It’s not 100%, but most are hydraulic rubber hoses. There are other materials as well, such as thermoplastic and PTFE. People mostly prefer nitrile, neoprene, and EPDM for hydraulic rubber hoses. FYI: Nitrile and neoprene rubber are suitable for chemical resistance.

Summary

Let’s wrap our discussion up!

Hydraulic systems are one of the most crucial parts of many industries. Its main job is to provide increased power to a system. It uses fluid power to lift heavy equipment or run machinery. You can also find its use in heavy-duty vehicles, like excavators, drill rigs, trucks, and more.

There is a wide range of hydraulic pipes. You have three options based on materials: hydraulic rubber hoses, thermoplastic, and PTFE. You also have three options based on standards: SAE, EN, and ISO. Moreover, considering reinforcement, you again have two options: spiral and braided.

When considering hydraulic rubber hoses, you still have many options: EPDM, nitrile, and neoprene.

As you can see, you have many options to choose from. Therefore, you must check what exactly your project needs. In this case, you can consider a few factors. As mentioned in our discussion, the right choice offers the most efficient solution.

If you have any questions about power hoses, please contact us. We manufacture a wide range of hoses, including many industrial hoses. Our customer support team is ready to provide you with a solution.