Material handling is a common task in every factory. People do it in various ways. For example, people move the raw materials here and there to prepare them. You must move the prepared material to different production places even if it is ready. In this case, a material handling hose plays a crucial role.

You may already understand what we are going to discuss today. This article will discuss various topics related to material handling hoses. Basically, what is a material handling hose? How many types are there, and what are their uses? These are the main topics here. Also, you will learn how to choose the correct material handling hoses. So, without delay, let’s start.

What is a Material Handling Hose?

As the name implies, a material-handling hose handles materials for various purposes. It is specially designed to move abrasive materials. Common abrasive materials are bulk powders, sand, and grains.

A material handling hose inner tube is made of PVC or polyurethane. Its reinforcement layer is often made of fabric plies with a wire helix. The reinforcement is responsible for the hose’s strength and elasticity.

The outer cover is made of black SBR rubber and a wrapped surface. SBR stands for styrene-butadiene rubber. The cover is necessary for the hose to withstand harsh conditions. This must resist abrasion as well.

A material-handling hose creates a secure passage for materials to flow through. The inner tube carries the material. In contrast, the outer cover and reinforcement layer handle the pressure and bending. The wire helix, on the other hand, maintains the hose shape.

A material-handling hose is prevalent in many applications. In the construction industry, it moves sand and cement. In manufacturing, it carries powders and grains. On the other hand, the food and beverage industry carries food-grade materials. You can also find material handling hoses in any mining job.

Overall, a material-handling hose ensures a safe and efficient material transfer. It comes in a wide range of sizes. You can choose the right option based on your project needs. We will discuss that in the later sections.

Properties of a Material Handling Hose

A material-handling hose uses three different types of materials. The inner tube is made of PVC or polyurethane. On the other hand, the reinforcement layer material is fabric plies with a wire helix. Finally, the outer cover is made of black SBR. The features and benefits mainly come from this material and overall construction.

(1) The material handling hose must be durable as it usually works in harsh environments. The support layer and the top cover are very important in this case.

(2) These rubber hoses are resistant to abrasion. This feature is compulsory when carrying abrasive materials.

(3) Rentone material handling hose is lightweight and robust. As a result, these rubber hoses are easy to maneuver.

(4) Rentone material handling hoses are easy to handle. Since they are lightweight, you can easily install and remove them. However, you must follow the proper instructions.

(5) These hoses can withstand various weather conditions. SBR works excellently in varying weather conditions. FYI: SBR rubber is used in car tires.

(6) Rentone material handling hoses can withstand temperatures from -40°F to +140°F (-40℃ – +60℃).

(7) These hoses are also versatile. They can transport a variety of abrasive materials. When choosing a hose, you must know which material you will transport.

Different Types of Material Handling Hoses

In the previous section, you learned what a material handling hose is. You’ve finished your first step in choosing a suitable material handling hose. Next, you’ll need to know what types of hoses are available. FYI: some bulk material handling hoses can not deal with dry materials. So, be careful when choosing a material handling hose.

Based on the market trends in 2024, five major types of material handling hoses are trendy. Each type has unique benefits and applications.

Type #1 Bulk Material Handling Hose

As the name suggests, these hoses transfer large quantities of materials. People use them to discharge bulk items like sand, limestone, and fertilizers. You may often find its use in agriculture, construction, and mining.

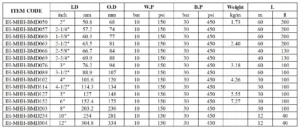

The inner diameter of these hoses is usually bigger than that of other hoses. Rentone Bulk Material Handling Hose has an inner diameter ranging from 50.8 mm to 304.8 mm. The outer diameter ranges from 68 mm to 334 mm. These hoses have a working pressure rating of 150 PSI or 10 bars. This pressure rating is enough for most types of bulk material handling.

Type #2 Sand Blasting Hose

Sandblasting is one type of surface preparation method. It uses high-pressure air to blast sand or other abrasive material onto a surface. This technique cleans the surface and gives a good look.

A sandblasting hose plays a crucial role in the sandblasting process. As you know, the method involves high pressure, so the hose must withstand it. Besides, operators move frequently with the blasting gun when cleaning metals. So, flexibility is a big concern here.

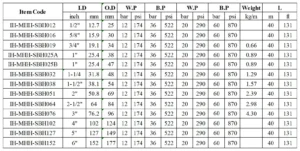

Sandblasting hoses generally have an inner diameter of 12.7 to 152 mm and an outer diameter of 25 mm to 177mm. The working pressure is 290 PSI or 60 bars.

Type #3 Food & Beverage Hose

Food and beverage hoses are specially designed for food products. They usually meet strict hygiene and safety standards. When buying these hoses, you must check the food grade certifications.

However, you may find these hoses in food processing, dairy, and beverage factories. They are typically flexible, easy to clean, and chemical resistant. They also do not interfere with the taste of the food being handled.

Type #4 Dry Material Handling Hose

Dry material transfer hoses are a type of bulk material handling hose. They mostly carry cement, dry sand, and grains. Dry material handling hoses are prevalent in the mining, construction, and cement industries.

Type #5 High-temperature Material Handling Hose

As the name suggests, these hoses are made for high-temperature jobs only. This means the hose must withstand high temperatures. People often look for hoses that can handle temperatures from -30 to +150 degrees Celsius.

The material used for the inner tube also matters a lot here. The PVC or polyurethane material has a temperature rating from -40 to +50 degrees Celsius. However, these materials are not effective for higher-term performance jobs. In these situations, you will need silicone. Silicone is a great rubber compound for high-temperature applications.

How to Choose the Right Industrial Hose for Material Handling

Besides knowing the basics about hoses and their types, you must also focus on other factors. These factors can help you determine the suitable material handling hose.

Factor #1 Know Your Application Needs

First, know your project needs. What is the purpose of the hose in your project? Is it for sandblasting or bulk material? Also, what type of material will it handle for the operation?

Factor #2 Handling Material

The handling material determines the type of hose you need. Is it sand or gavel? Does it handle food items that require hygiene? Some applications deal with chemicals, while others deal with waste or disposal. Also, some handle low temperatures, while some handle high temperatures.

Factor #3 Hose Construction

You must also consider hose construction. It ensures your project’s durability and performance. Indeed, a robust construction gives you an extended lifespan. A regular material transfer hose has three layers of construction. (1) Inner layer made of PVC or polyurethane. (2) The reinforcement layer is made of wire helix with fabric plies. (3) The outer cover is made of SBR rubber. For your information, a material handling hose guarantees a lifespan of 5 to 10 years.

Factor #4 Temperature Ratings

When selecting a material handling hose, you can’t overlook temperature rating. The heat directly impacts the inner tube. A PVC or polyurethane can handle -40 to 60 degrees Celsius. If the temperature exceeds this range, use silicone rubber for the inner tube.

Factor #6 Working Pressure

Material handling always encounters high pressure and may sometimes face impulse force. When choosing a material handling hose, first know your project’s working pressure. Find the best pressure rating for the hose based on your researched values. Note that the burst pressure must be three or four times the working pressure.

Factor #7 Type of Fittings and Connections

Fittings, also called connectors, attach hoses to equipment or machines. Their main job is to create a secure and leak-free connection. Always ensure the hose is compatible with the hose size and your project. There are different shapes and sizes of fittings. Click on the link attached to learn more about it.

Factor #8 Working Environment

The working environment is also a crucial factor. It affects the hose’s performance. There are many possibilities. Your project may handle chemicals, UV radiation, or moisture. Depending on the conditions, the construction material varies. In most cases, SBR is used to cover the outer hose. Note that SBR is used for car tires. This rubber is durable and can resist many weather factors.

Contact Us Today

Need help choosing the suitable material handling hose? Contact us today! Our experts are always here to assist you. Rentone Hose is a leading manufacturer of high-quality industrial hoses. We offer various types of industrial hoses, especially hydraulic hoses. Our products include hoses, spare parts, and fittings. Ready to discuss your project? Find any platform to contact our customer support. Feel free to ask any questions.