Oil hoses can be of many types and may differ in materials, grades, and applications. This huge market mainly results from different needs. For instance, a hydraulic system needs a high-pressure oil hose. This oil hose must be strong and withstand enough pressure for the job.

On the other hand, a car or motorcycle needs an engine oil hose. As you know, vehicles run in various weather conditions, so an oil hose. Similar situations can be observed in marine, extremely hot industrial settings, and more.

You can probably understand why and how this wide range of oil hoses emerged. However, this article highlights valuable information about oil hoses and their types. It provides detailed information that you may not find on other websites.

Hose or pipe importers, suppliers, and retail sellers can learn more about these types. The article offers valuable information they can use in their business strategies. So, without further delay, let’s get started.

What are Oil Hoses or Oil Pipes

Oil hoses or pipes are regular items. People also call them petroleum hoses. Oil hoses or pipes deliver all types of oils, including smooth and crude oils. For instance, hydraulic systems prefer special oils, and automobiles prefer engine oils. Different types of oils are used even in cooking. When handling these oils, people need specific types of oil hoses.

Flexibility

An oil hose is usually flexible and can be bent and twisted. You can install it anywhere you want. But you have to choose a suitable hose for this job. In this case, the rubber oil hose gives you the most flexibility. Other types, like metal braided or composite hoses, offer less flexibility.

Environmental Issue

An oil hose may experience different situations. You know, earth has varying climates. Some places are too cold, while some are too hot. Therefore, an oil hose must withstand these conditions.

Material Suitability

You may need to handle oil in many ways. For example, can you use an ordinary PVC pipe to supply hot oil to your project? No, you must select an oil hose that can withstand high heat. Generally, three materials are used in this case: rubber, plastic, and metal braid.

Different Types of Oil Hoses

Most of the oil hose types vary due to the different settings in which they are used. Therefore, you must find the right setting. If you fail to do so, you might face a few problems. (1) Excess cold and heat might crack the oil hose. (2) The wrong oil hose might not yield the best productivity. (3) You may experience many safety hazards. (4) You may need more replacement costs.

You will find many oil hoses if you ever go to a hose or pipe market. Finding the right one among so many options can be difficult. If you look carefully, you can divide them into three main categories. Material, application, and properties are the three main points you should consider. You will learn these types and their uses in the following three sections.

Types of Oil Hoses: By Materials

The material used in making oil hoses plays a crucial role. It mainly affects how well they work and where they can be used. Rubber, plastic, thermoplastic, metal braid, textile braid, and composite hoses are most common.

Rubber Oil Hose

An oil-resistant rubber hose is always a preferred option in most applications. As the name implies, this oil hose can stand against petroleum products. Rubber is flexible and works smoothly under varying weather conditions.

Nitrile is one of the most commonly used materials in this case. People prefer this material for applications involving temperatures between -32°C and +82°C (-26°F +180°F).

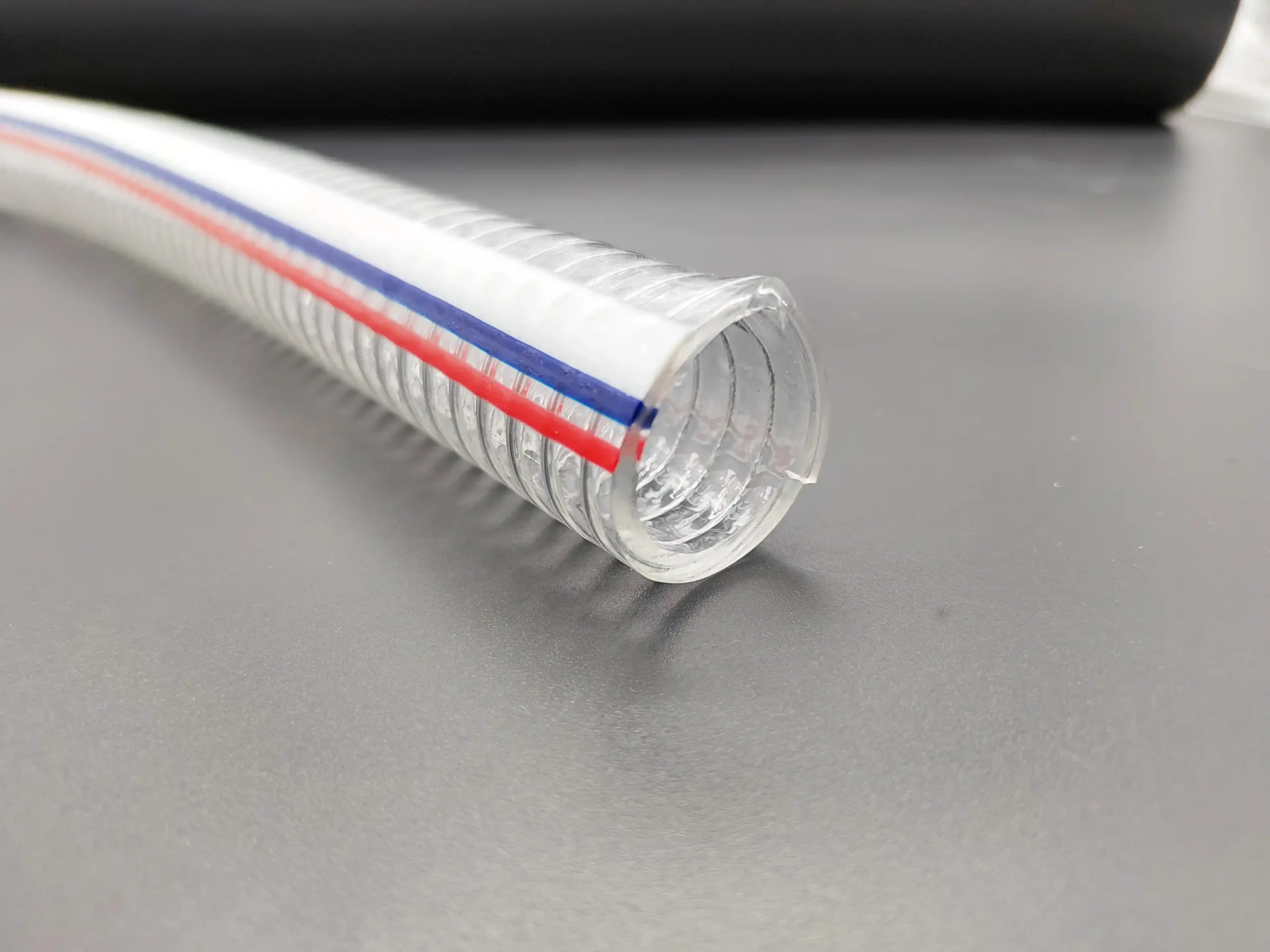

PVC Oil Hoses

PVC is lightweight and cheap. It is mostly suitable for chemical resistance. PVC oil hoses can be used for low-pressure oil delivery. People also use PVC oil hoses on various fuel lines in agriculture.

However, you may find two problems with PVC oil hoses. (1) It may be brittle in cold temperatures. (2) It may have limited resistance to other types of oil.

Thermoplastic Oil Hoses

A thermoplastic oil hose offers more flexibility and is lightweight. TPE is generally lighter than PVC. It also provides excellent temperature resistance, ranging from -200°C to +260°C (6500 F to 7250 F). Thermoplastic oil hoses are prevalent in hydraulic systems, industrial machinery, and mobile equipment.

Thermoplastics are more expensive than other materials. It may not be suitable for high-pressure jobs.

Metal braided oil hose

Metal braiding is one type of protection in hose shielding. It protects the oil hose from external impact. Consequently, a metal braided oil hose offers high strength and pressure ratings.

You can use these oil hoses in most medium to high-pressure jobs. You may often find its use in industry machines and hydraulic systems.

However, metal braided oil hose is heavier than other types. In addition, it is less flexible too.

Textile Braided Oil Hose

These oil hoses are reinforced with textile braid. This structure adds more strength to the oil hose while keeping it lightweight. Textile braided oil hoses are ideal for medium-pressure oil delivery and fuel systems.

Textile braided oil hoses are not suitable for high-pressure jobs. They may wear out faster under harsh conditions.

Composite Oil Hose

Composite oil hoses have multiple layers of different materials. They are highly chemical resistant and particularly suitable for delivering crude oil. They are often found in chemical plants and oil refineries. However, these oil hoses are expensive and may need special fittings.

Types of Oil Hose: By Applications

In addition to materials, you can also classify oil hoses into four types based on their uses. Once again, this diversity typically arises due to the demand for unique properties.

Hydraulic Oil Hose

Special oil used in hydraulic systems is called hydraulic fluid or hydraulic oil. As you know, hydraulic systems generate power at high pressures. Therefore, the hydraulic oil hose must withstand this pressure to work smoothly.

There are different types of hydraulic pipes. (1) Braided Hydraulic Hose. (2) Spiral Hydraulic Hose. (3) Thermoplastic Hydraulic Hoses.

Fuel Delivery Hose

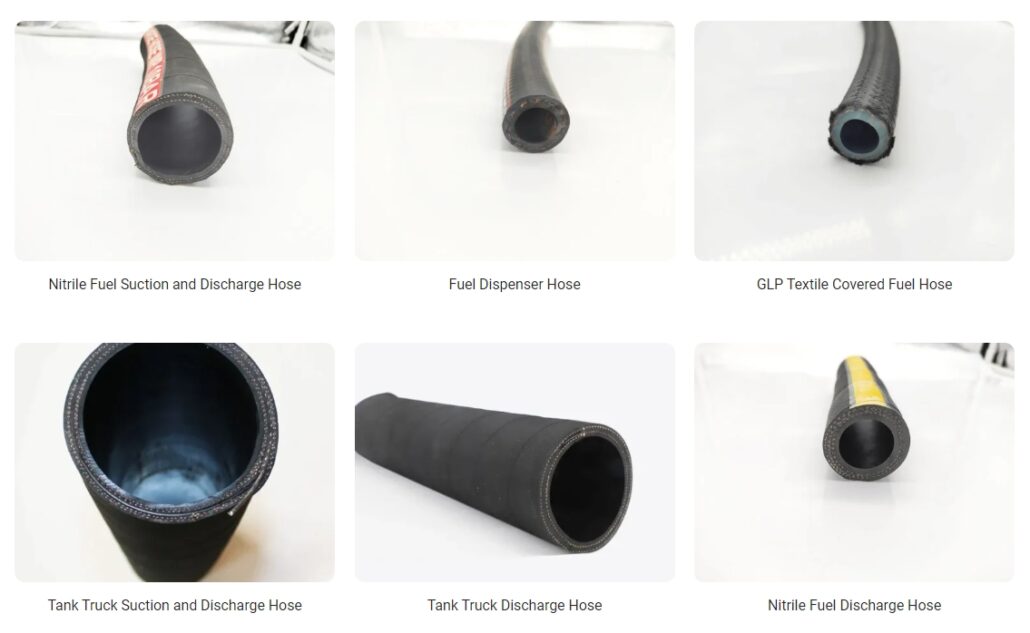

A fuel oil delivery hose is also known as a dispenser fuel oil hose, which may have different names based on applications, such as engine oil hoses. However, whatever the name, fuel delivery hoses are used in fuel pumps and delivery systems. They can resist chemicals in fuels and prevent leaks.

Moreover, these oil pipes are highly flexible and durable. Most fuel delivery systems use rubber, PVC, and thermoplastic hoses.

Suction and Discharge Oil Hoses

Suction and discharge oil hoses are particular types of petroleum products. They usually handle both suction (vacuum) and discharge (pressure) tasks. These hoses often come with reinforcement. Note that this unique structure helps them withstand both suction and discharge stress. People commonly use these hoses to transfer oil to and from storage tanks, trucks, and vessels.

Tank Truck Oil Hoses

As the name suggests, these oil hoses are used in tank trucks. They help transfer petroleum to and from storage tanks and tanker trucks. These pipes usually have a larger diameter, ranging from 63 mm to 172 mm. The working pressure is 160 PSI or 10 bars; the burst pressure is 450 PSI or 30 bars. However, you can customize the lengths and diameters at Rentone Hose Factory.

Other Industrial Oil Hose

You can find other industrial oil hoses besides the above. Although their working principles may be similar, they have some differences. Textile-covered fuel hoses, fuel dispenser hoses, steel pipes, and discharge hoses are noteworthy.

Types of Oil Hoses: By Properties

You can also categorize petroleum hoses by their physical characteristics. What should you consider in this case? Pressure, flexibility, and stress are three crucial factors to consider.

- Flexible petroleum hose is typically soft and light. It actually doesn’t have any metal reinforcement. The typical flexible materials are rubber and PVC. In contrast, composite hoses and metal braided hoses are less flexible.

- High-stress pipes are perfect for heavy-duty jobs. You can find them in construction and factories.

- Oil-pressure hoses are excellent for high-pressure jobs. Most hydraulic hoses are in this group.

- Low-pressure hoses are, consequently, suitable for low-pressure jobs. You may need these pipes for lubrication, low-pressure oil delivery, and general upkeep.

Types of oil hoses: By Grades

Likewise, oil hoses can be divided by grade. There are three common grades: regular, premium, and food grade.

- Regular grade is the one you use every day. For example, lay-flat oil hoses are perfect for everyday use.

- Premium grade is the updated version, like thermoplastics. TPE is generally better than PVC. Although more expensive than PVC, it offers high heat and pressure resistance.

- Food-grade deals with edible oils.

Rentone Hose Products & Services

Rentone Hose is a leading manufacturer of industrial hoses. This company produces a variety of oil hoses. However, you can also order custom sizes and types. In addition, their services include rapid prototyping and 24-hour customer service.

Above all, if you have any questions, contact their customer support team. For any hoses, pipes, or tubes, click the contact button and send your questions.